Product Introduction

Mirrordick High-Precision Mirror EDM machine AD Series is specifically developed for industries requiring ultra-fine surface finish and ultimate machining precision. Equipped with a spark oil temperature control system, this series delivers exceptional machining stability—critical for products demanding uniform surface texture. Three-color operational indicator lights provide remote status visualization, ensuring safe production and enhancing machining efficiency. It offers mold manufacturers an unmanned, intelligent precision manufacturing solution.

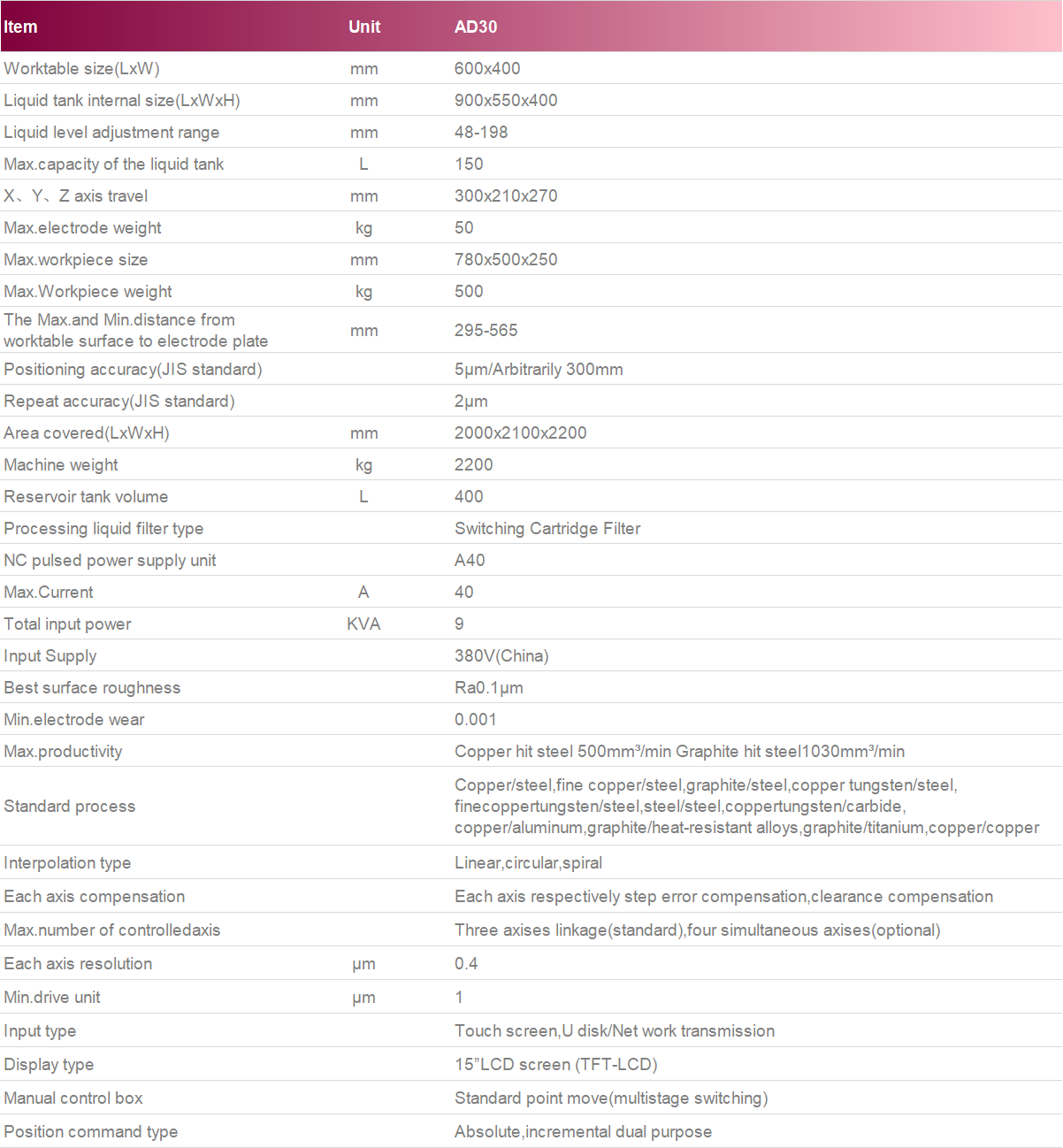

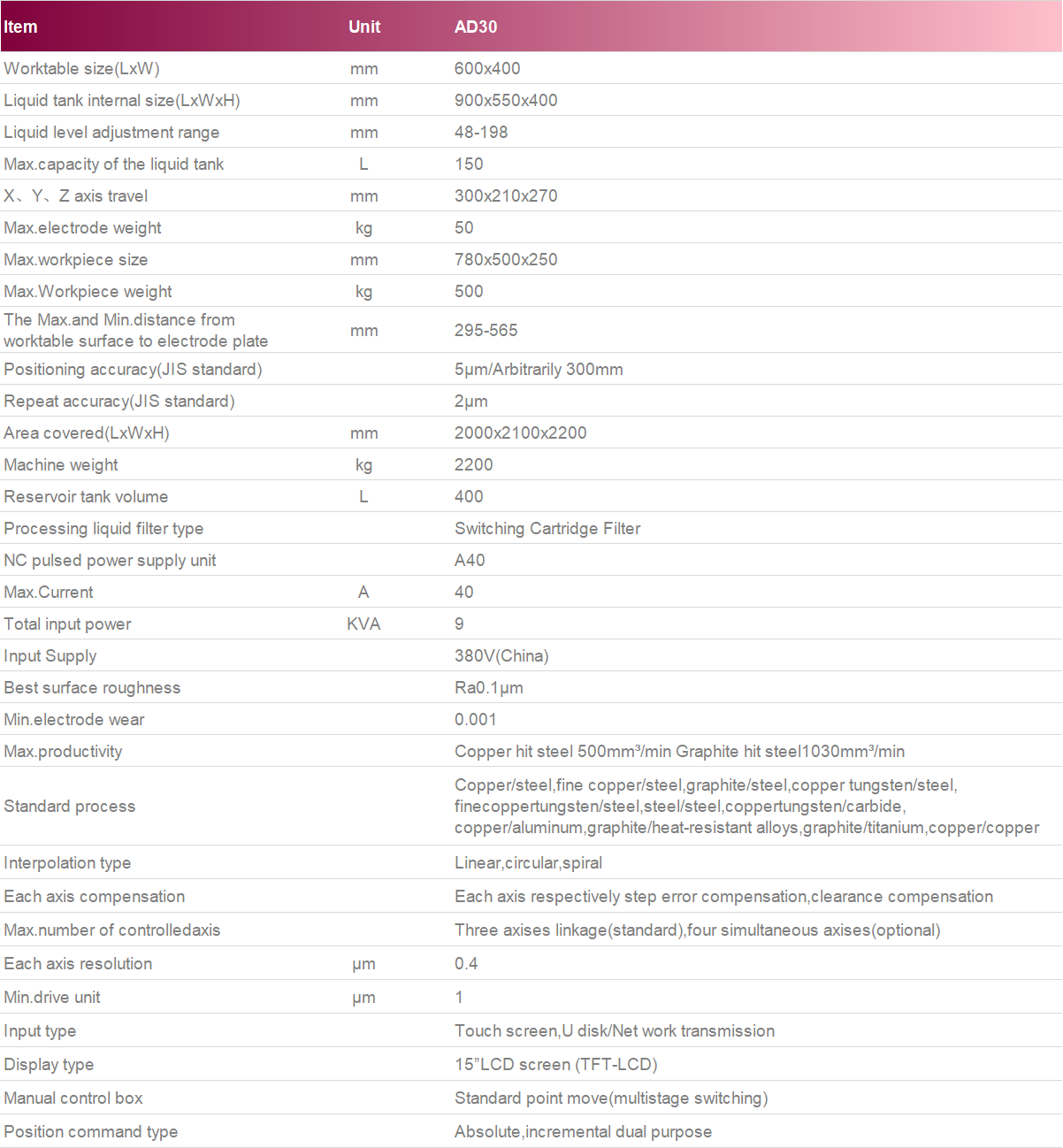

Technique Parameters

Key Features

▶Windows operating system, standard networking function and file transmission,it can be extended to remote wireless operation/dynamic monitoring and to realize internet +automated intelligent production line

▶60 work-pieces coordinate system can be displayed, programming-free,CNC machining programme can be generated automatically according to the interface parameters system

▶The discharge parameters can be modified in real time without suspending during discharge machining

▶According to the processing requirements,the height and interval of the long tool can be set to facilitate slag discharge

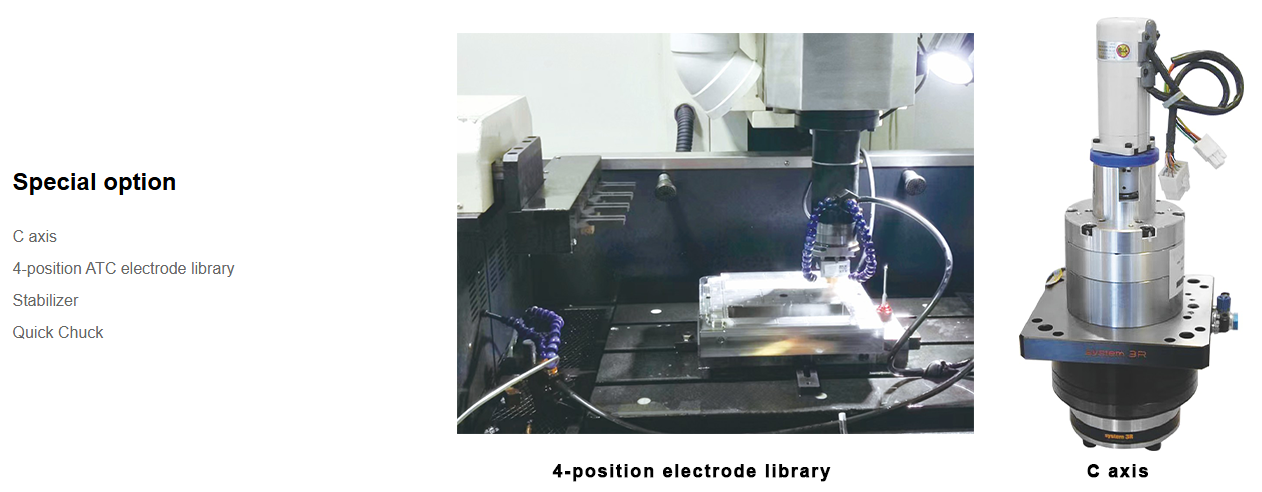

▶With a variety of processing functions: 3-axies to multi-axes different trajectory linkage processing, multi-hole automatic shift processing of porous position, transverse processing,45-degree oblique processing, inverted buckle processing, grain surface mirror processing etc., high processing efficiency, small loss of superior processing performance

▶The system is equipped with independent discharge circuits for a variety of material processing: Copper hit steel,graphite hit steel,copper-tungsten hit carbide, copper hit zinc alloy, graphite hit zinc alloy,copper hit copper alloy etc.

▶Made of natural marble, the worktable will move while the head remains stationary during machining

Product Advantages

Tailor-Made Solutions – Unlike conventional EDM machines, the AD30 can be customized for different industries and applications.

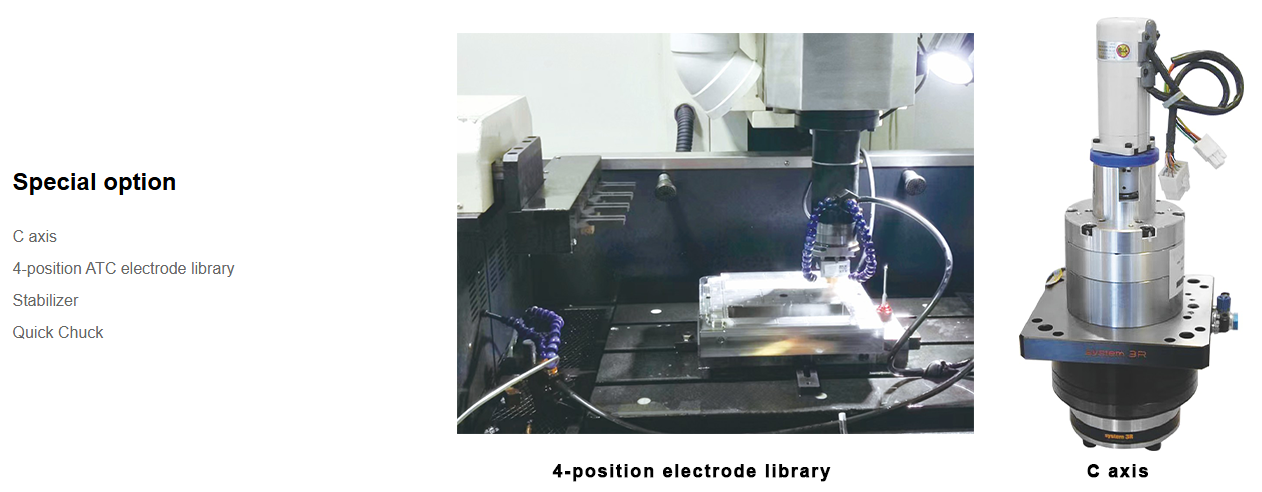

Superior Productivity – Automated electrode libraries and intelligent controls minimize downtime and reduce operator workload.

Global Service Commitment – Mirrordick provides free system upgrades, lifetime technical support, and process consultation.

Reduced Manufacturing Costs – High surface quality eliminates the need for extensive post-processing and polishing.

Future-Ready Technology – Industry 4.0 compatibility ensures smooth integration with smart manufacturing environments.

Reliable Quality Assurance – Built with patented innovations and strict quality standards, ensuring consistent long-term performance.

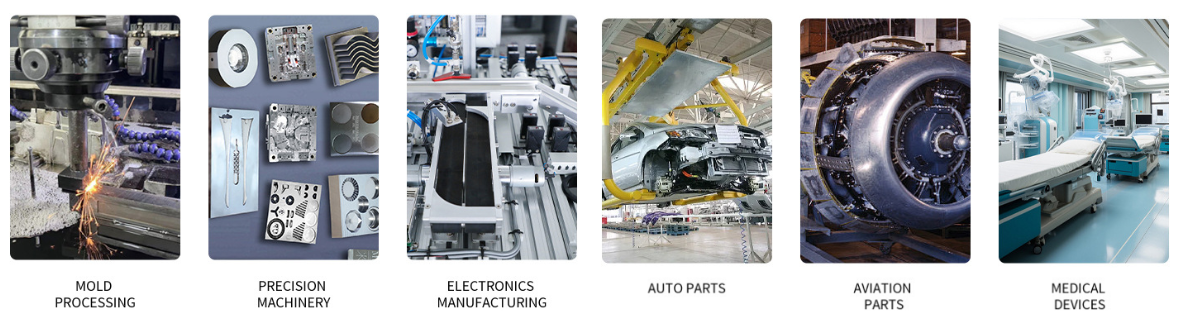

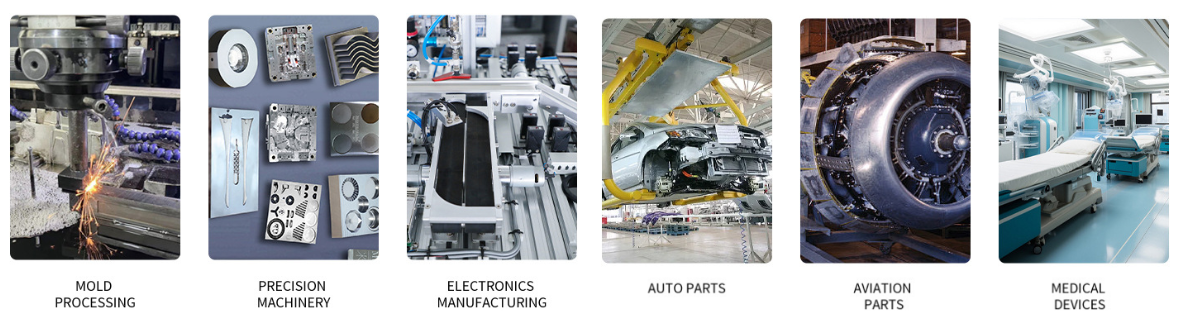

Application Fields

The AD30 CNC EDM machine has broad applications across industries that demand precision, reliability, and mirror-finish quality:

Mold Manufacturing – Injection molds, die-casting molds, precision tooling for plastics and metals.

Automotive Industry – Precision parts, connectors, and critical engine components.

Aerospace Engineering – Complex parts with stringent dimensional tolerances.

Medical Technology – Surgical tools, implants, and micro-scale components.

Electronics Industry – Connectors, semiconductor housings, and precision metal components.

Tool & Die Production – Custom small-batch or mass production dies with fine details.

FAQ (Frequently Asked Questions)

Q1: What sets the AD30 apart from other EDM machines?

A1: The AD30 is unique because it offers customized processing configurations. Customers can select features that match their production needs, ensuring maximum flexibility and cost-effectiveness.

Q2: Can the AD30 be upgraded in the future?

A2: Yes. The modular design allows for system upgrades, automation integration, and software updates, ensuring long-term scalability.

Q3: What industries benefit most from the AD30?

A3: The AD30 is widely used in mold making, automotive, aerospace, medical, and electronics industries, particularly where mirror-finish quality and tight tolerances are required.

Q4: How does Mirrordick support customers after purchase?

A4: We provide free lifetime technical support, processing guidance, and software upgrades, ensuring customers can maximize the machine’s potential.

Q5: What surface roughness can the AD30 achieve?

A5: The AD30 is capable of achieving mirror-like surface finishes, reducing the need for secondary polishing and saving processing time.

Phone

Phone