Product Introduction

Mirrordick High-Precision Mirror EDM machine AD Series is specifically developed for industries requiring ultra-fine surface finish and ultimate machining precision. Equipped with a spark oil temperature control system, this series delivers exceptional machining stability—critical for products demanding uniform surface texture. Three-color operational indicator lights provide remote status visualization, ensuring safe production and enhancing machining efficiency. It offers mold manufacturers an unmanned, intelligent precision manufacturing solution.

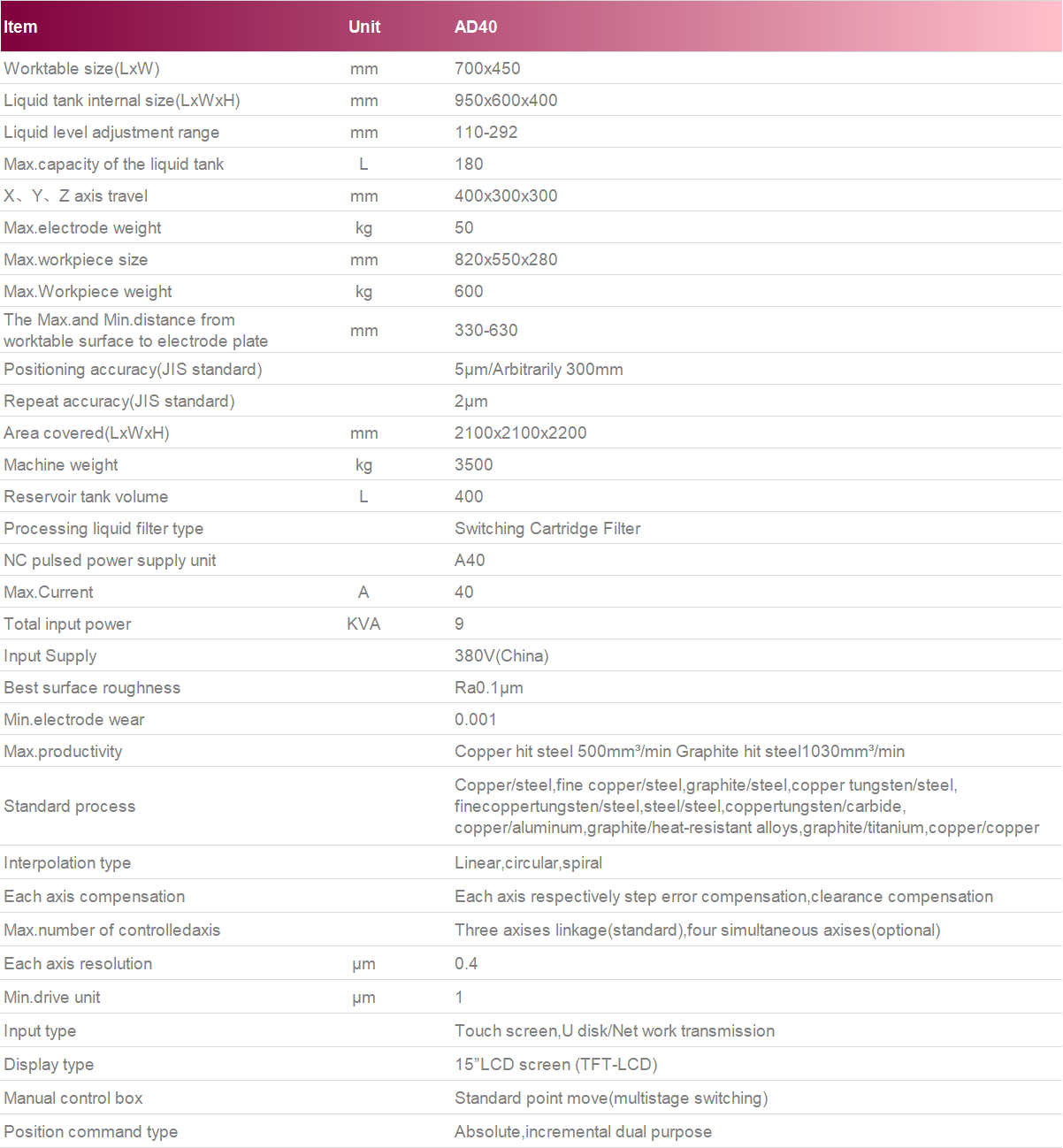

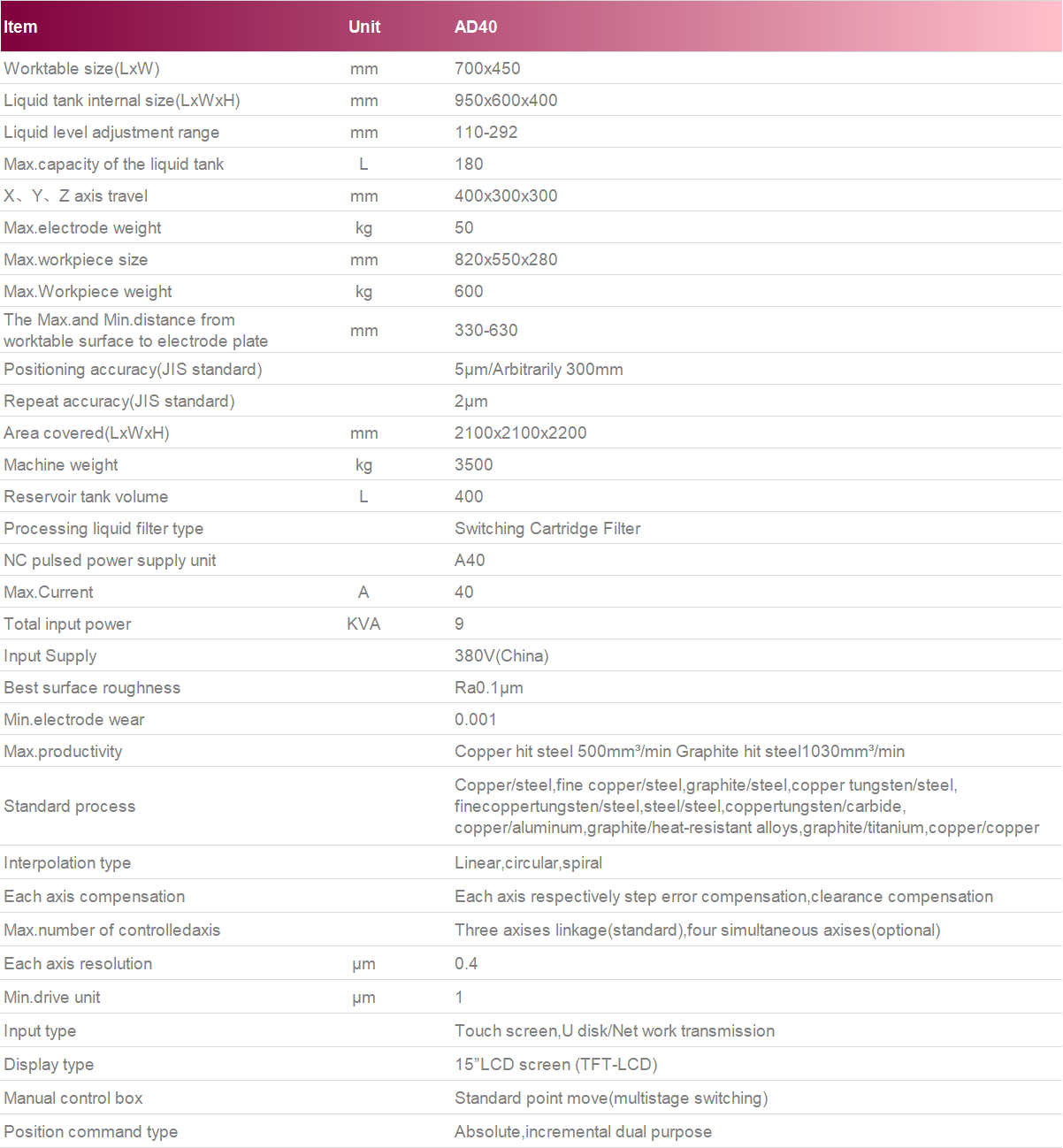

Technique Parameters

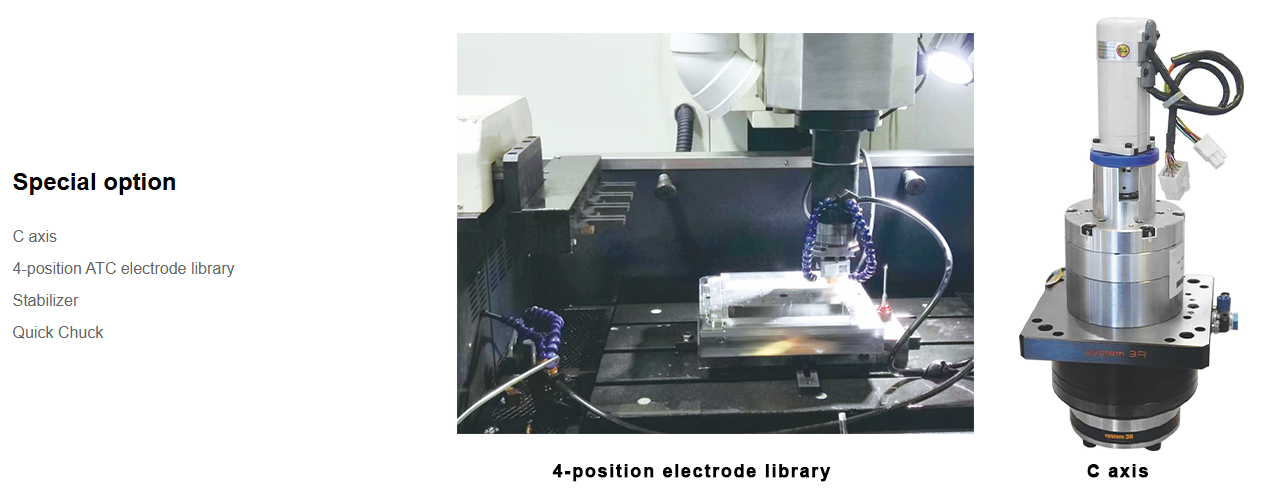

Key Features

▶Windows operating system, standard networking function and file transmission,it can be extended to remote wireless operation/dynamic monitoring and to realize internet +automated intelligent production line

▶60 work-pieces coordinate system can be displayed, programming-free,CNC machining programme can be generated automatically according to the interface parameters system

▶The discharge parameters can be modified in real time without suspending during discharge machining

▶According to the processing requirements,the height and interval of the long tool can be set to facilitate slag discharge

▶With a variety of processing functions: 3-axies to multi-axes different trajectory linkage processing, multi-hole automatic shift processing of porous position, transverse processing,45-degree oblique processing, inverted buckle processing, grain surface mirror processing etc., high processing efficiency, small loss of superior processing performance

▶The system is equipped with independent discharge circuits for a variety of material processing: Copper hit steel,graphite hit steel,copper-tungsten hit carbide, copper hit zinc alloy, graphite hit zinc alloy,copper hit copper alloy etc.

▶Made of natural marble, the worktable will move while the head remains stationary during machining

Product Advantages

Superior Productivity – Faster discharge rates and automation reduce downtime and boost throughput.

Smart Factory Integration – Fully compatible with Industry 4.0 manufacturing environments, allowing real-time monitoring and data exchange.

Cost Reduction – Minimized secondary processing lowers operational costs and labor intensity.

Flexibility in Processing – Suitable for small-batch production as well as mass manufacturing in multiple industries.

Lifetime Support – Mirrordick provides free system upgrades, process consulting, and global after-sales services.

Proven Reliability – Backed by patented core technologies and mechanical innovation awards.

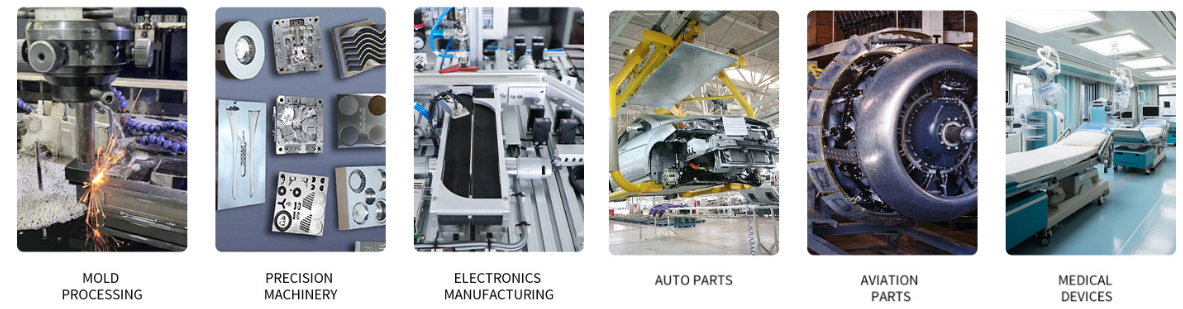

Application Fields

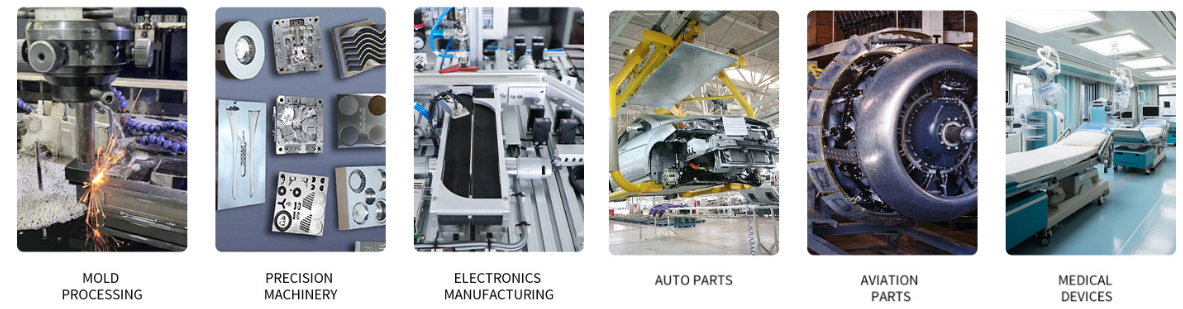

The AD40 EDM machine tool is designed for diverse industrial sectors that require high precision, mirror finishes, and long-term reliability:

Precision Mold Industry – Plastic injection molds, die-casting molds, and fine stamping molds.

Electronics & Semiconductor – Connectors, IC molds, and micro-precision components.

Automotive Manufacturing – Complex engine parts, transmission components, and precision tooling.

Aerospace & Defense – High-strength alloys and aerospace-grade precision parts.

Medical Industry – Surgical tools, implants, and custom-designed medical components.

Industrial Tooling – Small-scale production and prototype machining for advanced tooling.

FAQ (Frequently Asked Questions)

Q1: What type of materials can the AD40 machine process?

A1: The AD40 is capable of machining conductive materials including hardened steel, tungsten carbide, copper, and specialty alloys used in mold and high-precision manufacturing.

Q2: How does the AD40 improve efficiency compared to traditional EDM machines?

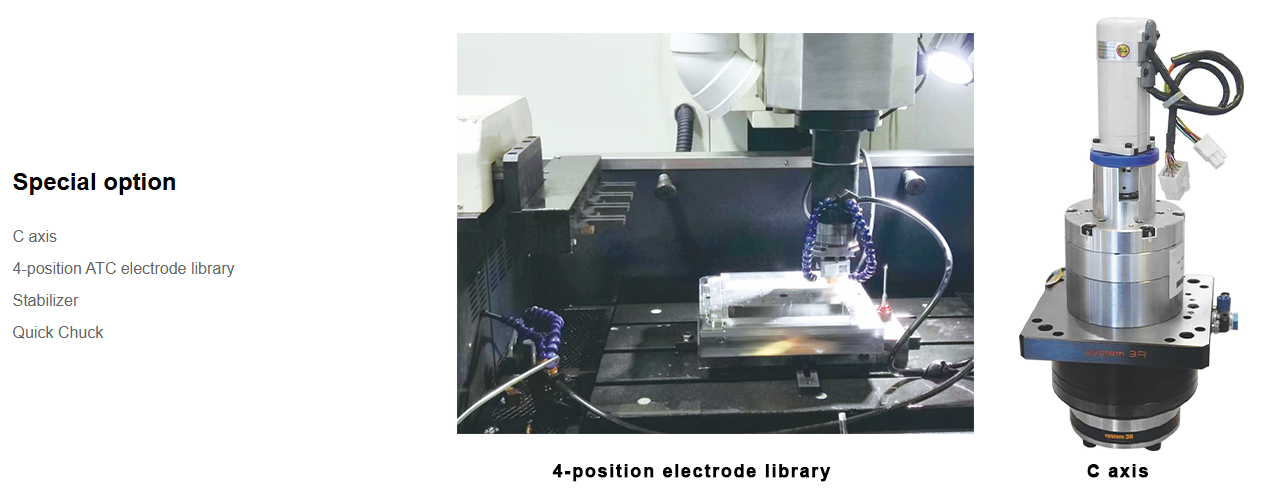

A2: The AD40 integrates multi-station electrode libraries, automatic oil systems, and intelligent CNC programming, which significantly reduces setup time, minimizes operator intervention, and increases continuous machining efficiency.

Q3: Is the AD40 suitable for Industry 4.0 environments?

A3: Yes. With its Windows-based platform, automated data ports, and real-time communication functions, the AD40 is fully compatible with smart manufacturing and MES systems.

Q4: What kind of surface finish can the AD40 achieve?

A4: The AD40 can produce mirror-like surfaces with extremely low roughness, making it suitable for industries that require ultra-smooth finishes such as optics, electronics, and medical devices.

Q5: What after-sales support does Mirrordick provide?

A5: Customers enjoy lifetime free technical support, free system upgrades, and professional processing consultation, ensuring worry-free ownership and maximum machine performance.

Phone

Phone