Product Introduction

Mirrordick High-Precision Mirror EDM machine A Series is a classic model. It features a machine body made of Meehanite cast iron meeting FC300 or higher standards, paired with a natural marble worktable for stable machining performance. The system incorporates a PIKA ultra-precision mirror discharge circuit and provides 66 workpiece coordinate systems. It meets the high standards of the automotive, aerospace, and precision mold industries, representing a cost-effective choice proven by long-term market validation.

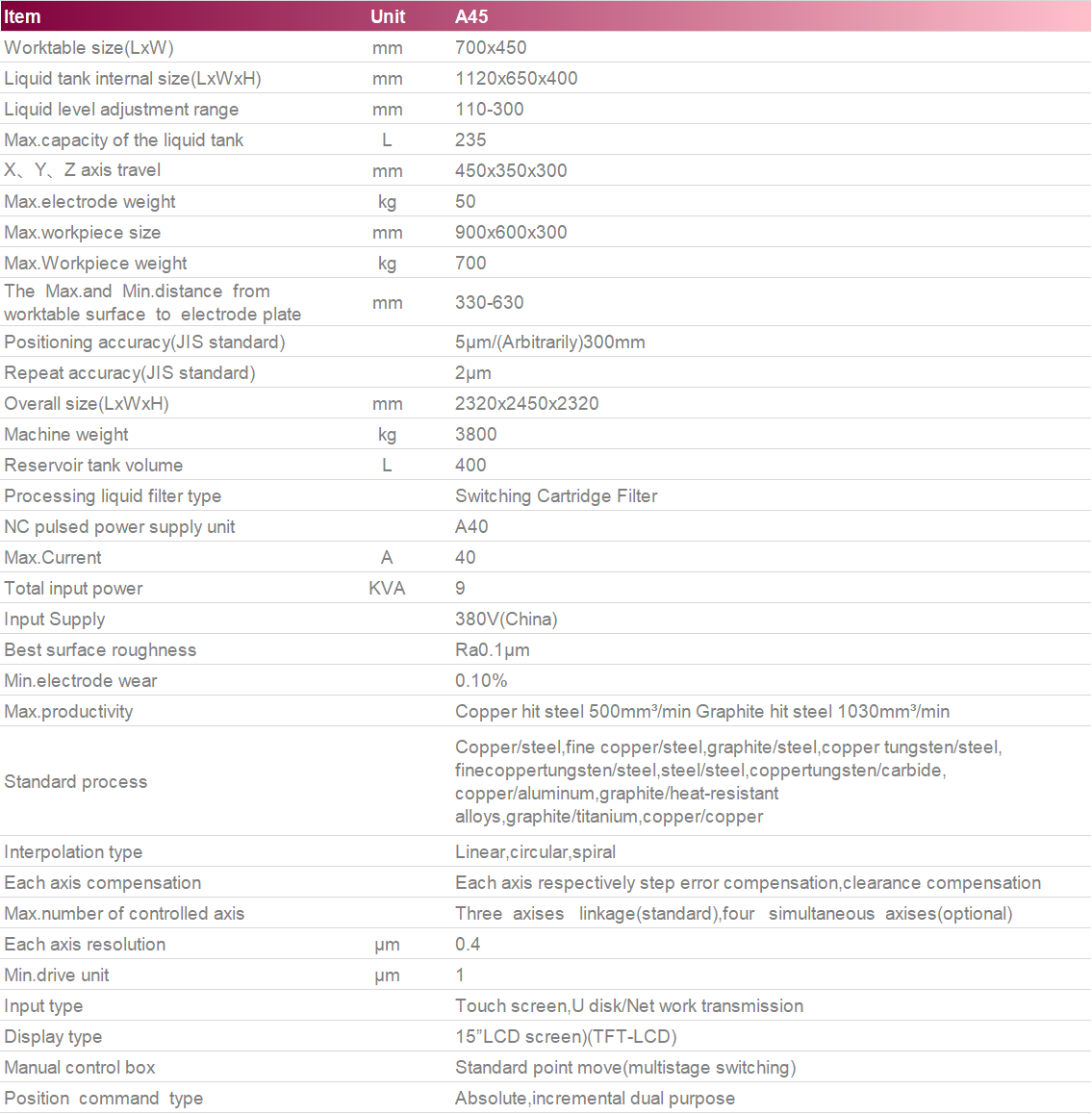

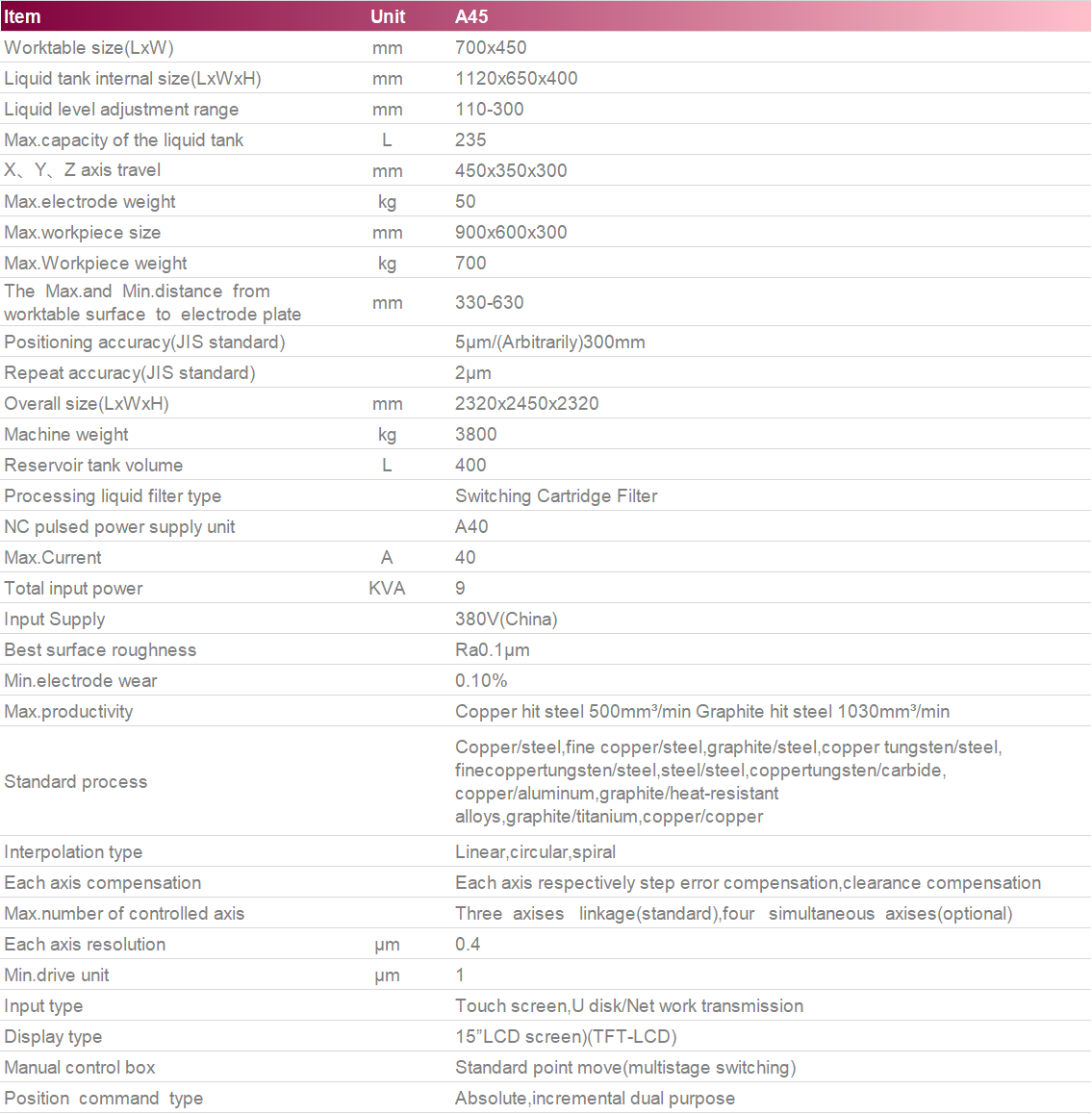

Technique Parameters

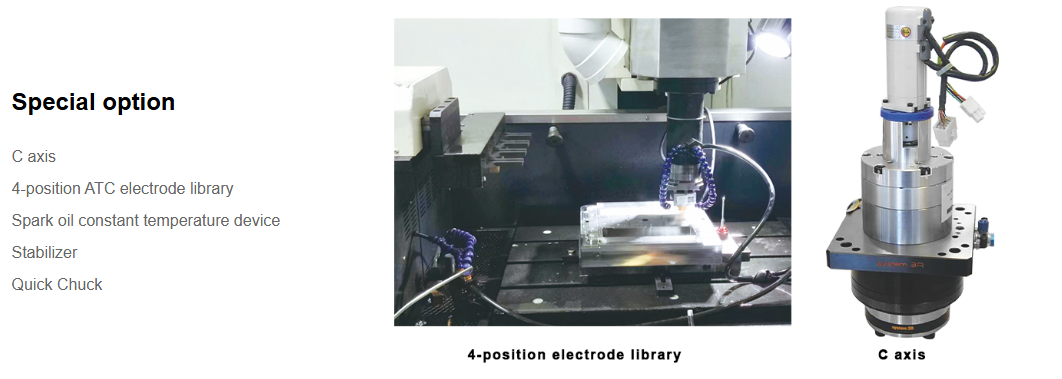

Key Features

▶Windows operating system, standard networking function and file transmission,it can be extended to remote wireless operation/dynamic monitoring and to realize internet +automated intelligent production line

▶60 work-pieces coordinate system can be displayed, programming-free,CNC machining programme can be generated automatically according to the interface parameters system

▶The discharge parameters can be modified in real time without suspending during discharge machining

▶According to the processing requirements,the height and interval of the long tool can be set to facilitate slag discharge

▶With a variety of processing functions: 3-axies to multi-axes different trajectory linkage processing, multi-hole automatic shift processing of porous position, transverse processing,45-degree oblique processing, inverted buckle processing, grain surface mirror processing etc., high processing efficiency, small loss of superior processing performance

▶The system is equipped with independent discharge circuits for a variety of material processing: Copper hit steel,graphite hit steel,copper-tungsten hit carbide, copper hit zinc alloy, graphite hit zinc alloy,copper hit copper alloy etc.

▶Made of natural marble, the worktable will move while the head remains stationary during machining

Product Advantages

Unmatched Surface Quality – The A45 is engineered for mirror-level finishing, eliminating the need for extensive polishing.

Industry 4.0 Ready – Open data connectivity allows seamless integration with smart factories and MES systems.

Higher Production Efficiency – Automation reduces manual intervention, cuts downtime, and increases overall productivity.

Cost-Effective Investment – Reduces secondary processing and labor costs, ensuring faster return on investment.

Global After-Sales Support – Mirrordick offers lifetime free technical support, system upgrades, and professional consulting services.

Proven Reliability – Built with patented core technologies, the A45 guarantees long-term stability and consistent machining accuracy.

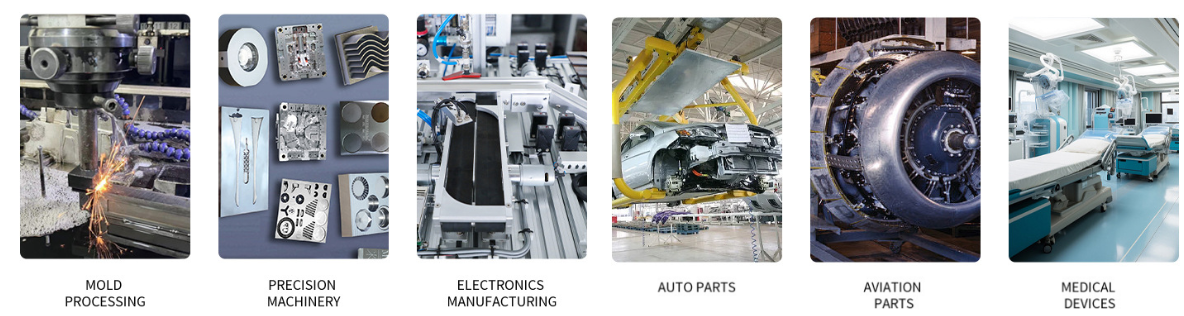

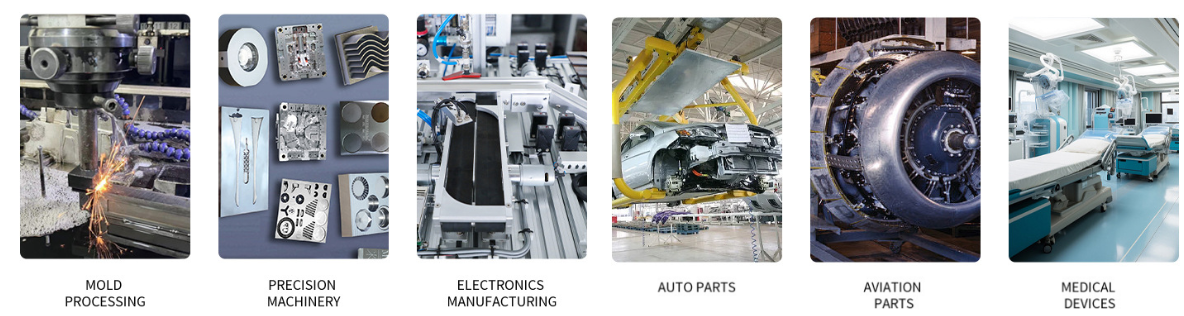

Application Fields

The A45 mirror EDM machine is widely used in industries where precision, surface quality, and reliability are critical:

Mold Manufacturing – Plastic molds, die-casting molds, precision injection molds.

Automotive Industry – High-precision automotive components and connectors.

Aerospace – Complex parts requiring high accuracy and durable finishes.

Medical Equipment – Surgical instruments, implants, and components with stringent tolerance requirements.

Electronics – Connectors, semiconductor molds, and precision housings.

Tool & Die Industry – Small-batch, complex tooling solutions.

FAQ (Frequently Asked Questions)

Q1: What makes the A45 different from other EDM machines?

A1: The A45 is specifically designed for mirror-surface finishing with high precision, integrating automation features such as ATC and 3D online detection, making it suitable for Industry 4.0 manufacturing.

Q2: Can the A45 be integrated into automated production lines?

A2: Yes. The machine is equipped with a Windows-based control system and open automated data ports, allowing smooth integration into networked production lines and smart factory systems.

Q3: What types of materials can the A45 machine process?

A3: The A45 is capable of machining hardened steel, copper, tungsten carbide, and other conductive materials used in mold and precision part manufacturing.

Q4: How does the A45 improve production efficiency?

A4: With its multi-station electrode library, automatic oil tank lifting, and real-time 3D detection, the A45 minimizes downtime, reduces manual intervention, and enhances machining precision.

Q5: What after-sales services are provided?

A5: Mirrordick offers free lifetime technical support, free processing technology consultation, and system upgrades, ensuring customers can always operate the machine with confidence.

Phone

Phone