Product Introduction

The AM-Series Single-Head EDM offers higher load capacity, wider work travel, and superior efficiency, making it the preferred choice for medium and large mold manufacturing.

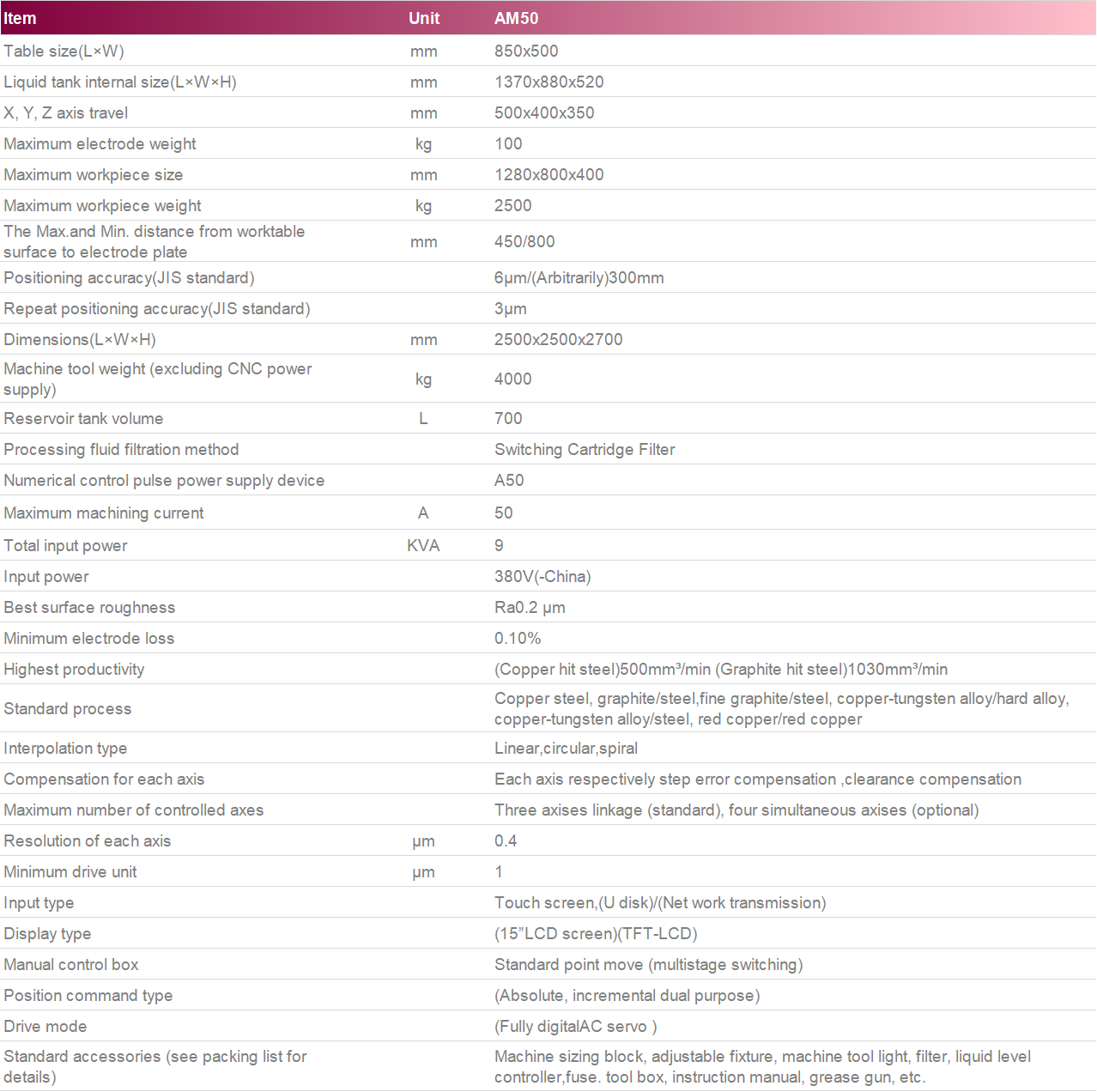

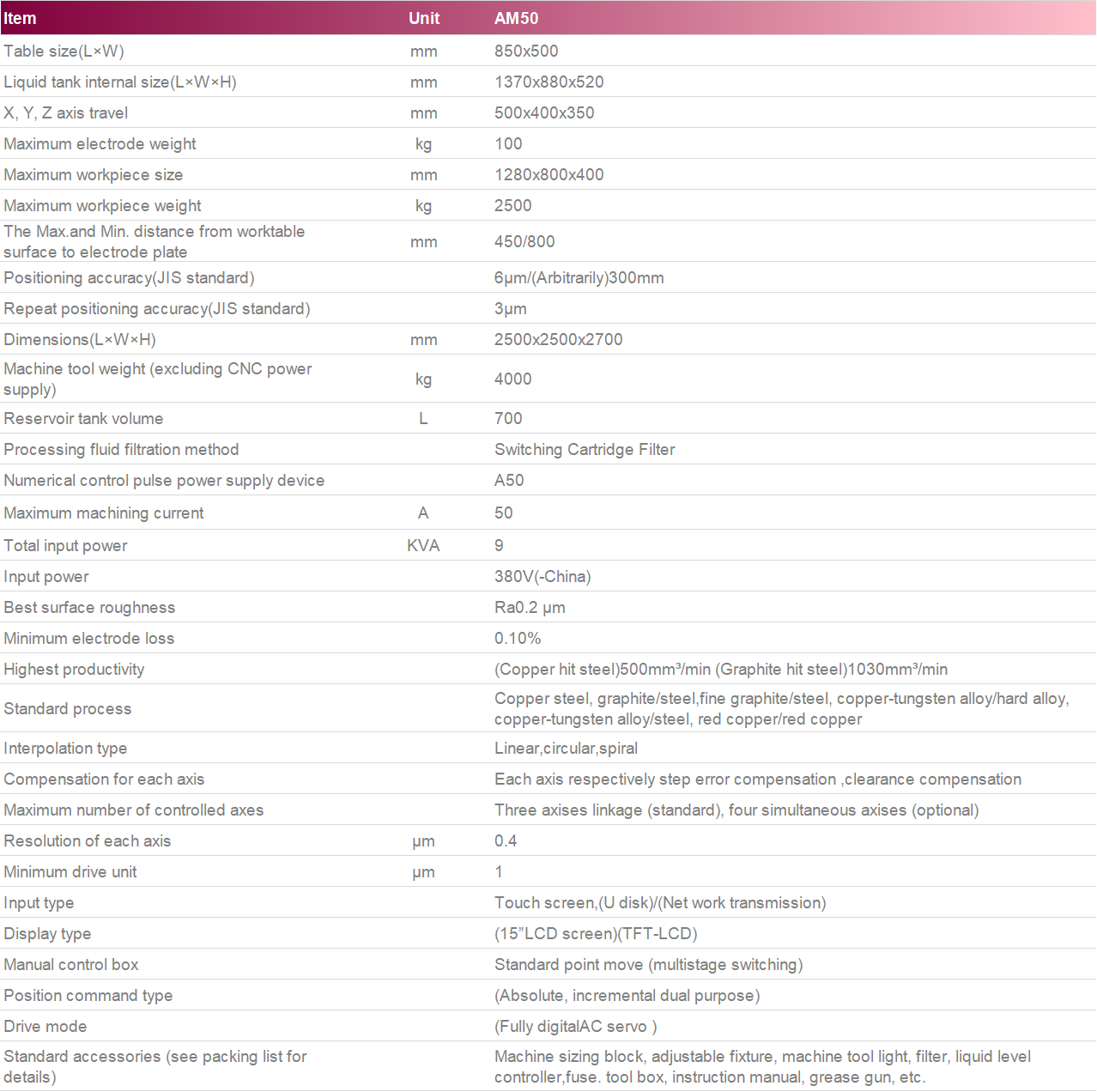

Technique Parameters

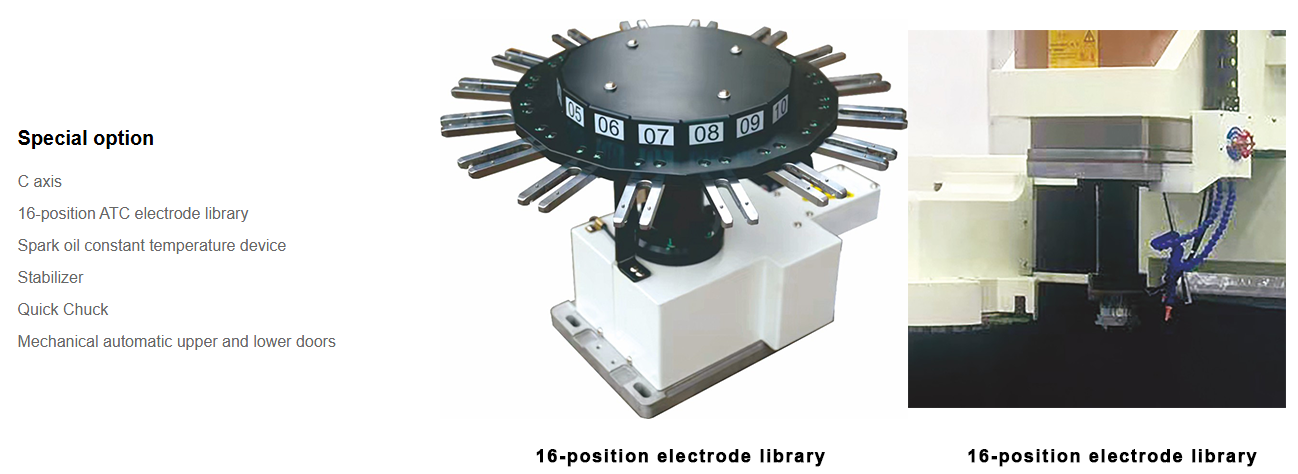

Key Features

▶Windows operating system, standard networking function and file transmission,it can be extended to remote wireless operation/dynamic monitoring and to realize internet +automated intelligent production line

▶60 work-piece coordinate system can be displayed, programming-free,CNC machining programme can be generated automatically according to the interface parameters system

▶The discharge parameters can be modified in real time without suspending during discharge machining

▶According to the processing requirements,the height and interval of the long tool can be set to facilitate slag discharge

▶With a variety of processing functions:3-axies to multi-axes different trajectory linkage processing, multi-hole automatic shift processing of porous position, transverse processing,45-degree oblique processing, inverted buckle processing, grain surface mirror processing etc., high processing efficiency, small loss of superior processing performance

▶The system is equipped with independent discharge circuits for a variety of material processing: Copper hit steel,graphite hit steel,copper-tungsten hit carbide, copper hit zinc alloy, graphite hit zinc alloy,copper hit copper alloy etc.

▶Made of casting iron, the worktable remains stationary while the head move during machining

Core Advantages

Achieves mirror-level surface finishes (Ra ≤ 0.1µm) efficiently.

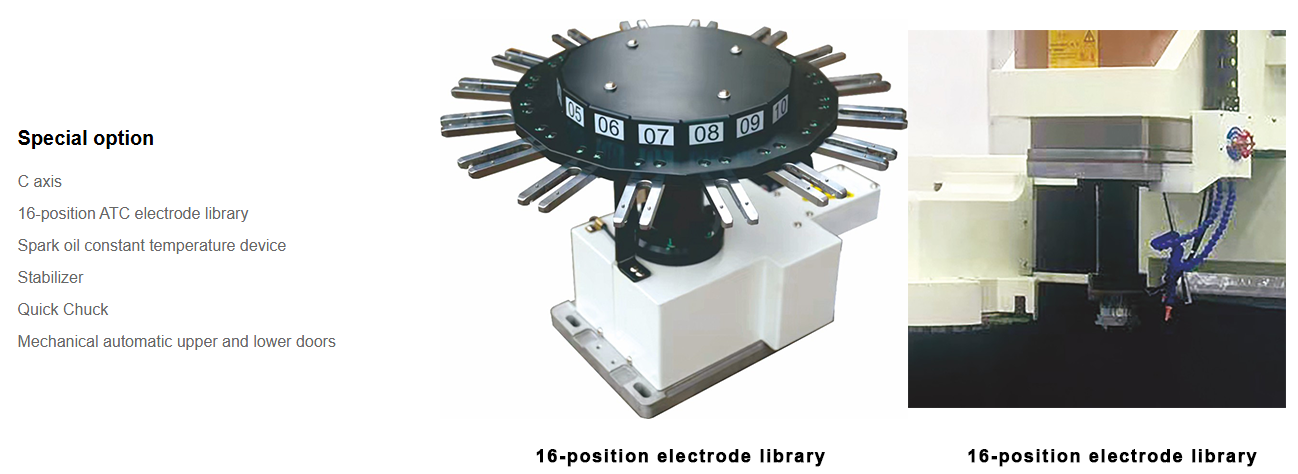

Significantly reduces machining time with automated electrode change and positioning.

Ideal for hard materials like titanium, carbide, and hardened steel.

Easy to integrate into smart production lines with open data port and network support.

Comes with lifelong free system upgrades and technical support.

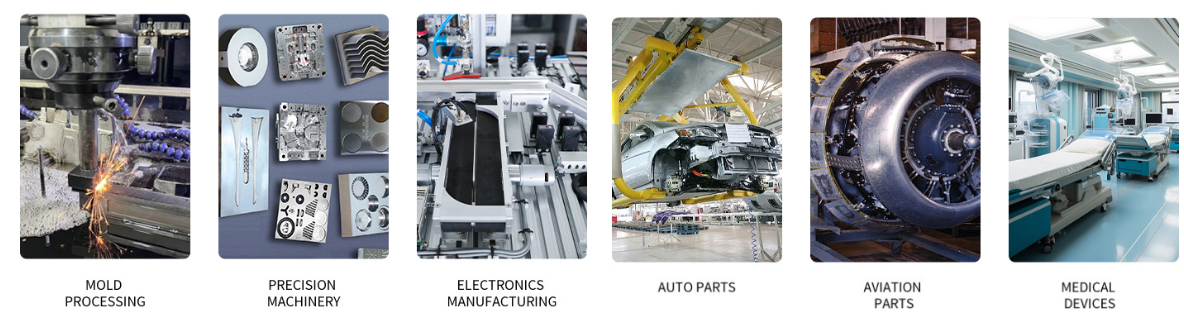

Application Industries

Mold & Die: Injection molds, die-casting molds, precision stamping dies.

Medical Devices: Surgical instruments, implants, and micro-components.

Aerospace: Turbine blades, engine components, lightweight structures.

Automotive: Gears, transmission parts, high-precision sensors.

Electronics: Micro-connectors, semiconductor parts, precision fixtures.

Frequently Asked Questions (FAQ)

Q1: What surface roughness can the AM50 achieve?

A: It can achieve mirror-like finishes with surface roughness as low as Ra 0.1 µm.

Q2: Is the machine compatible with automation systems?

A: Yes, it supports automation integration through data open ports and offers options like ATC and robotic loading.

Q3: What materials can be processed with the AM50?

A: It effectively machines conductive materials including carbide, titanium, tool steel, and superalloys.

Q4: Do you provide technical support after purchase?

A: Yes, we offer lifelong free system upgrades and unlimited technical support.

Q5: Can the machine perform 3D inspection?

A: Yes, with the optional 3D on-machine measurement system.

Phone

Phone