Product Introduction

Mirrordick AM200R is an advanced electrical discharge machine developed for manufacturers who seek superior mirror-like surface quality and high repeatability. Built with a rigid structure and equipped with a high-precision CNC system, the AM200R ensures minimal electrode wear and consistent performance even during long production runs. Its dual-head design allows simultaneous machining of two identical or different workpieces, dramatically improving productivity. With capabilities such as oil tank auto-lifting, data interface openness, and network transmission support, the AM200R is well-suited for smart factories and Industry 4.0 environments.

Special option

Spark oil constant temperature device

Electric control box thermostat

Stabilizer

Quick Chuck

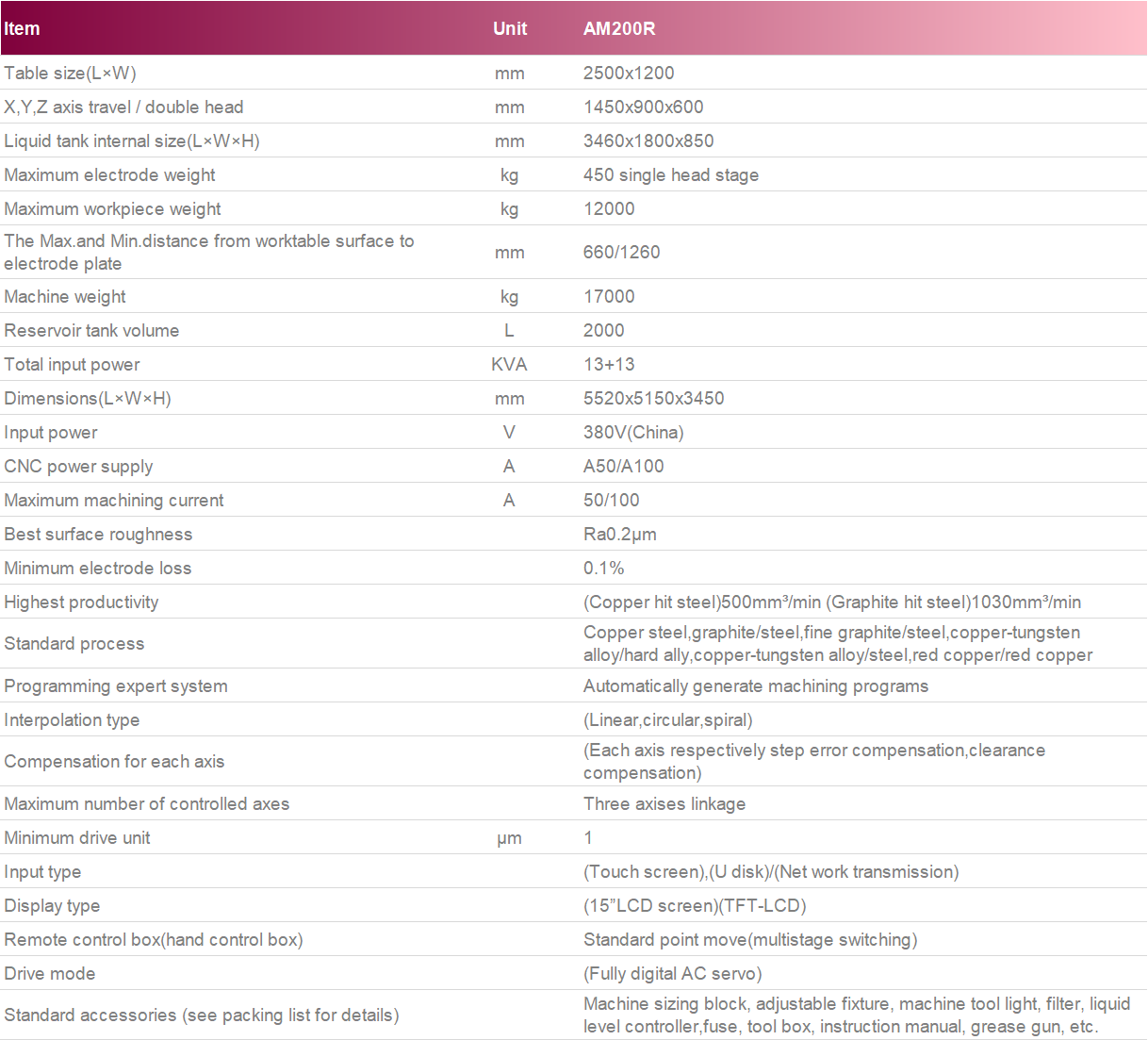

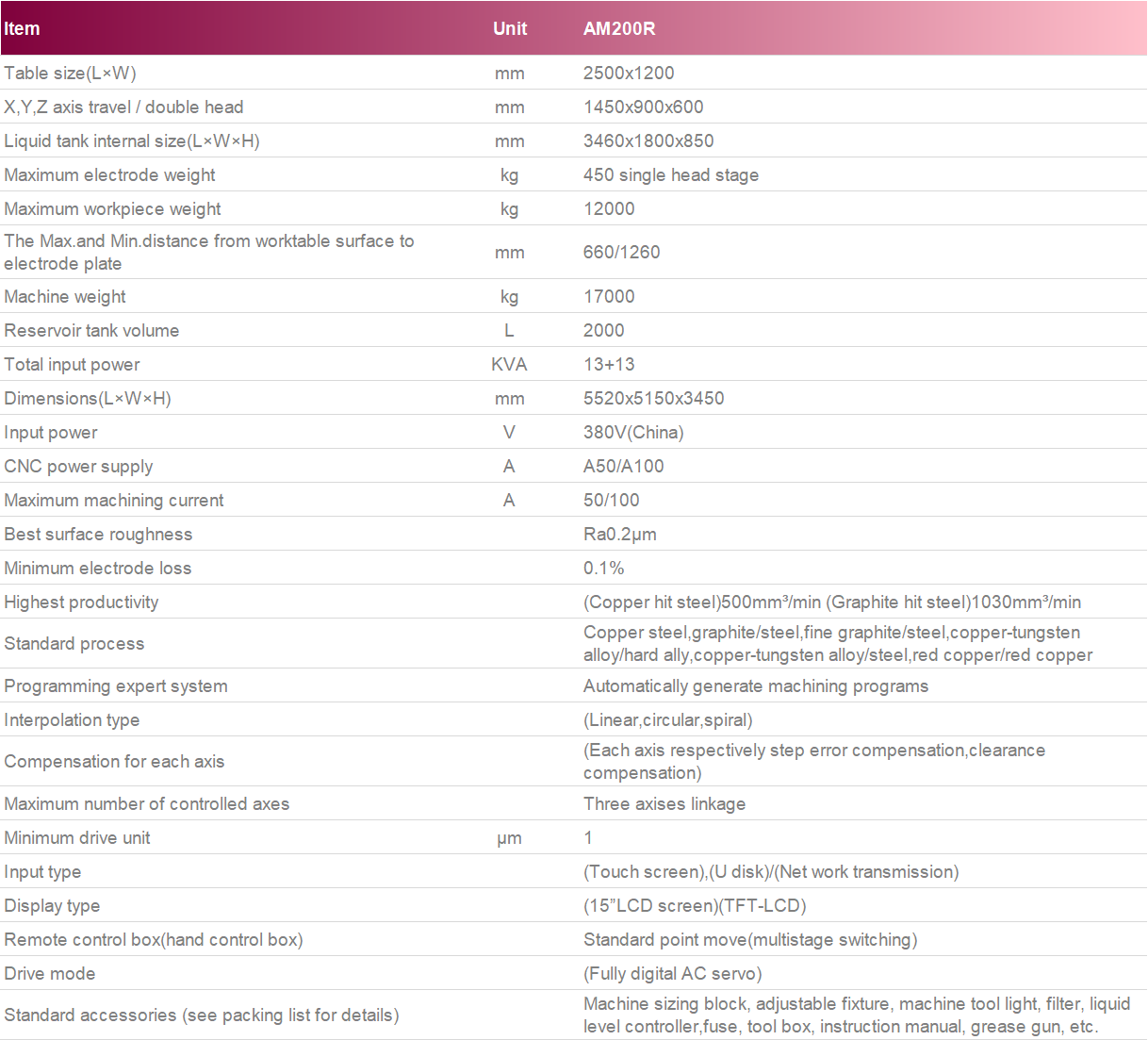

Technique Parameters

Key Features

▶Windows operating system, standard networking function and file transmission,it can be extended to remote wireless operation/dynamic monitoring and to realize internet +automated intelligent production line

▶60 work-pieces coordinate system can be displayed, programming-free,CNC machining programme can be generated automatically according to the interface parameters system

▶The discharge parameters can be modified in real time without suspending during discharge machining

▶According to the processing requirements,the height and interval of the long tool can be set to facilitate slag discharge

▶With a variety of processing functions: 3-axies to multi-axes different trajectory linkage processing, multi-hole automatic shift processing of porous position, transverse processing,45-degree oblique processing, inverted buckle processing, grain surface mirror processing etc., high processing efficiency, small loss of superior processing performance

▶The system is equipped with independent discharge circuits for a variety of material processing: Copper hit steel,graphite hit steel,copper-tungsten hit carbide, copper hit zinc alloy, graphite hit zinc alloy,copper hit copper alloy etc.

▶Made of natural marble, the worktable will move while the head remains stationary during machining

Advantages

High Efficiency: Dual-head design and AEC (Auto Electrode Changer) reduce idle time and increase throughput.

Superior Precision: Patented pulse power supply and intelligent adaptive control ensure extreme accuracy.

Ease of Use: Simplified programming and automation features reduce operator dependency.

Low Maintenance: Robust construction and premium components extend machine life and reduce downtime.

Technical Support: Mirrordick offers lifelong free system upgrades and unlimited process support.

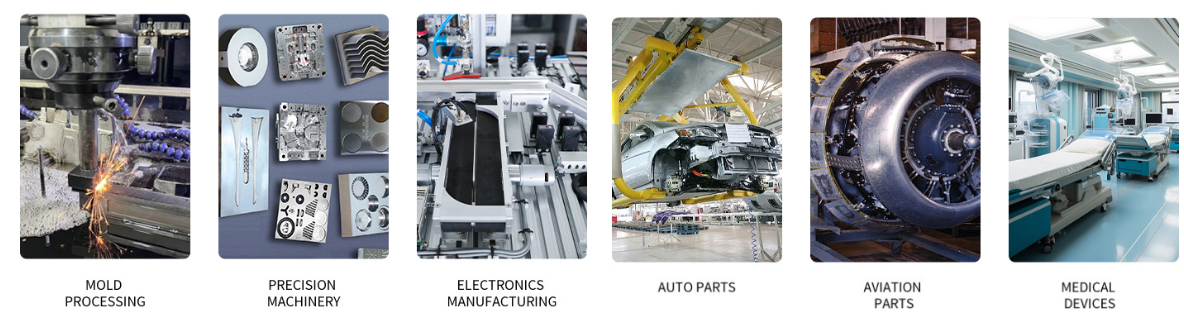

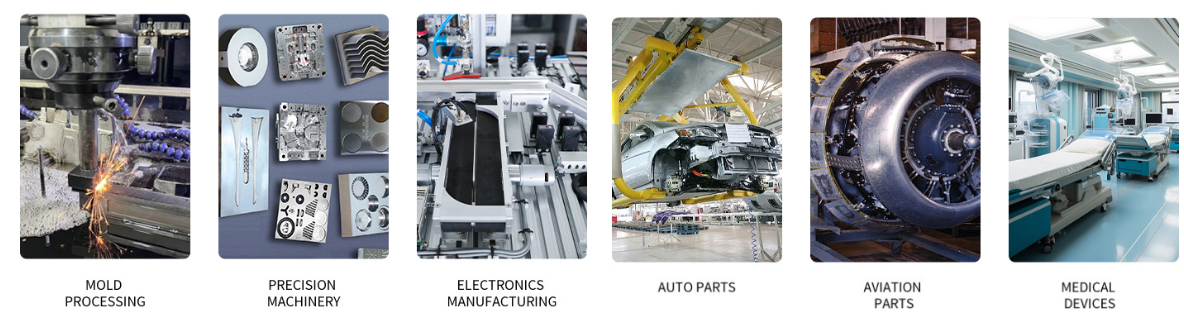

Application Industries

Mold & Die Making: Injection molds, die-casting molds, forging dies.

Medical Device Manufacturing: Surgical instruments, implants, and micro-components.

Aerospace & Automotive: Turbine blades, fuel injection nozzles, gears, and transmission parts.

Electronics & Micro-Machining: Connectors, semiconductor parts, and precision gears.

Optical and Consumer Goods: Lens molds, watch components, and cosmetic packaging molds.

Frequently Asked Questions (FAQ)

Q1: What surface roughness can the AM200R achieve?

A: The AM200R can achieve mirror-like surface quality with roughness as low as Ra ≤0.1μm.

Q2: Does it support automated production lines?

A: Yes, it comes with an open data interface and supports network connectivity for integration into automated cells and IoT systems.

Q3: What kind of training or support is provided?

A: Mirrordick provides installation guidance, operational training, and lifelong free technical and software support.

Q4: How does the dual-head function work?

A: The two machining heads can operate simultaneously or independently, allowing parallel processing of two identical or different parts.

Q5: Is the machine suitable for graphite electrodes?

A: Yes, it works with both copper and graphite electrodes and includes anti-electrolysis pulse technology for fine finishes.

Phone

Phone