Product Introduction

The AM-Series Single-Head EDM offers higher load capacity, wider work travel, and superior efficiency, making it the preferred choice for medium and large mold manufacturing.

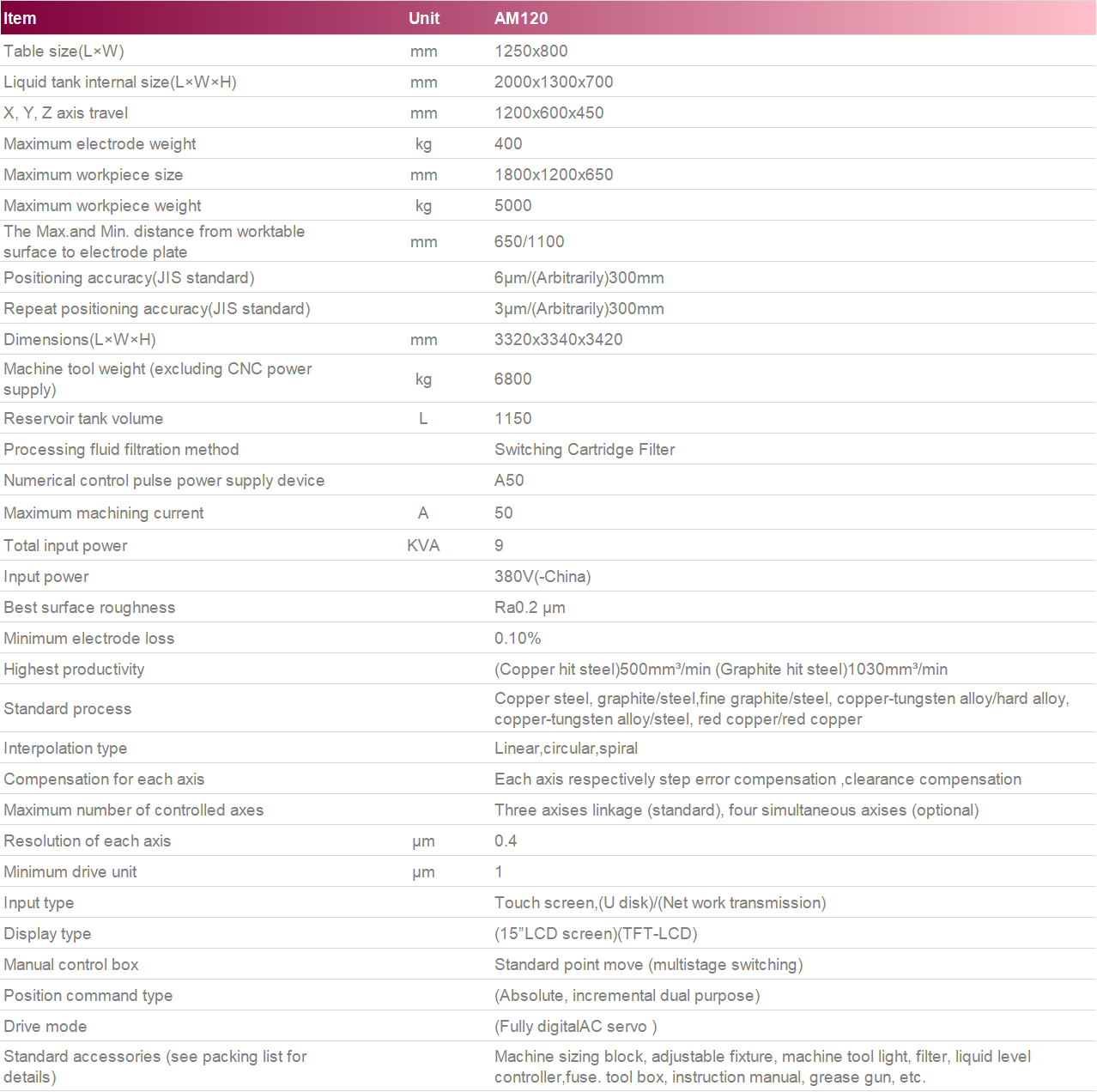

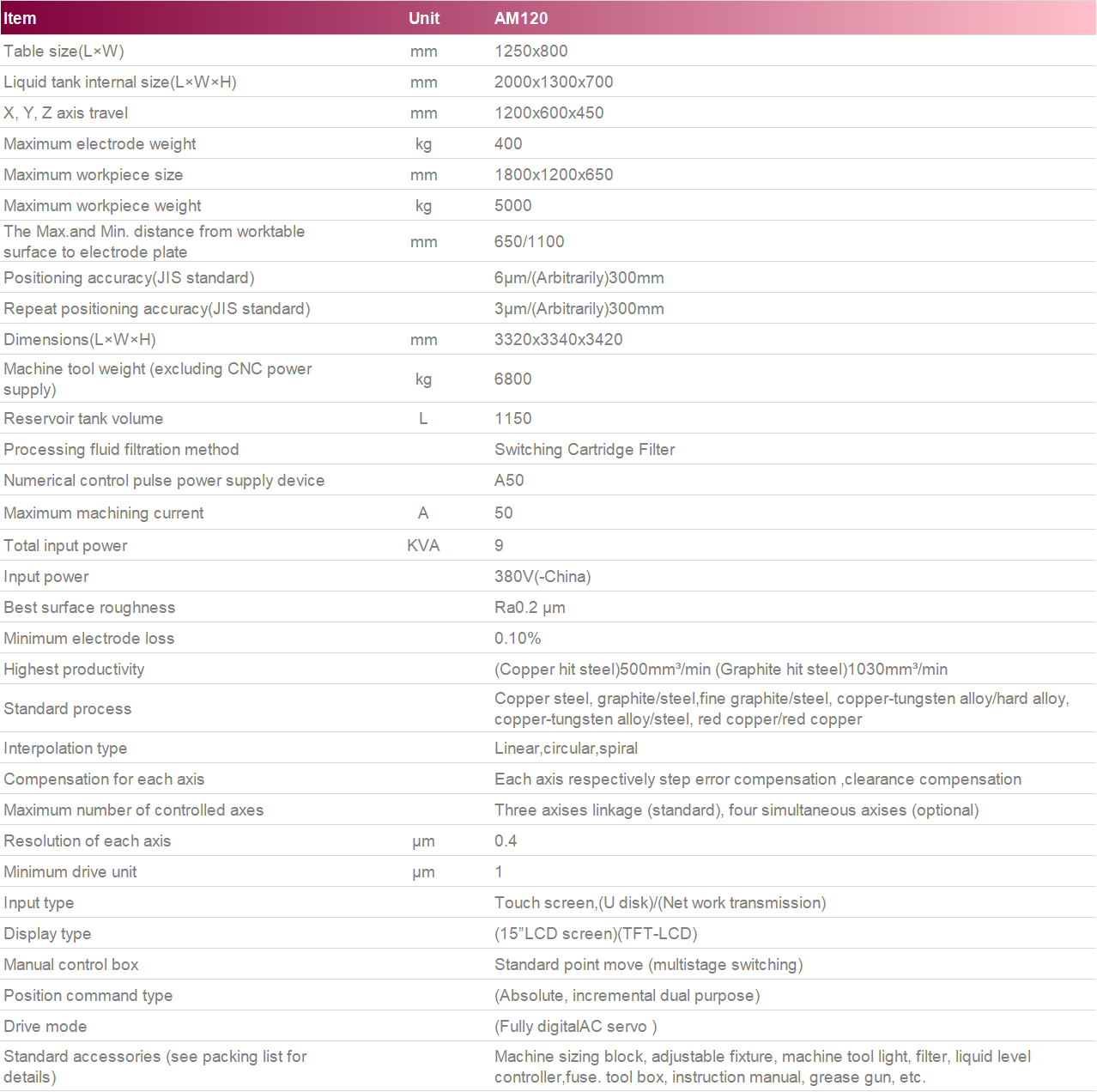

Technique Parameters

Key Features

▶Windows operating system, standard networking function and file transmission,it can be extended to remote wireless operation/dynamic monitoring and to realize internet +automated intelligent production line

▶60 work-pieces coordinate system can be displayed, programming-free,CNC machining programme can be generated automatically according to the interface parameters system

▶The discharge parameters can be modified in real time without suspending during discharge machining

▶According to the processing requirements,the height and interval of the long tool can be set to facilitate slag discharge

▶With a variety of processing functions: 3-axies to multi-axes different trajectory linkage processing, multi-hole automatic shift processing of porous position, transverse processing,45-degree oblique processing, inverted buckle processing, grain surface mirror processing etc., high processing efficiency, small loss of superior processing performance

▶The system is equipped with independent discharge circuits for a variety of material processing: Copper hit steel,graphite hit steel,copper-tungsten hit carbide, copper hit zinc alloy, graphite hit zinc alloy,copper hit copper alloy etc.

▶Made of natural marble, the worktable will move while the head remains stationary during machining

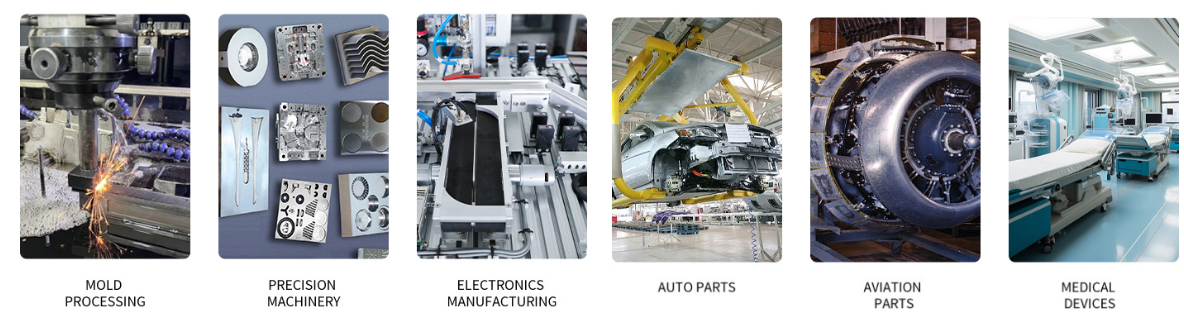

Application Industries

Precision Mold & Die Manufacturing: Ideal for manufacturing intricate cavities, cores, and inserts for plastic injection molds, die-casting dies, and stamping dies.

Aerospace Industry: Perfect for machining heat-resistant alloys and creating complex cooling channels in turbine blades and other critical components.

Medical Device Manufacturing: Used for producing high-precision, corrosion-resistant components for surgical instruments and medical implants.

Automotive Industry: Applications in producing key components for engines, transmissions, and custom automotive parts.

Fine Jewelry & Watchmaking: Capable of creating intricate details and textures on molds for jewelry and watch components.

Frequently Asked Questions (FAQ)

Q1: What is the typical surface roughness (Ra) the AM120 can achieve?

A: Under optimal parameters, the AM120 can achieve a mirror-like finish with surface roughness as low as Ra 0.1μm or even better, depending on the workpiece material.

Q2: Is the Windows CNC system easy to learn for a new operator?

A: Yes. Our intuitive Windows-based interface is much easier to learn than traditional DOS-based EDM controls, reducing training time and minimizing operational errors.

Q3: Can this machine run unattended?

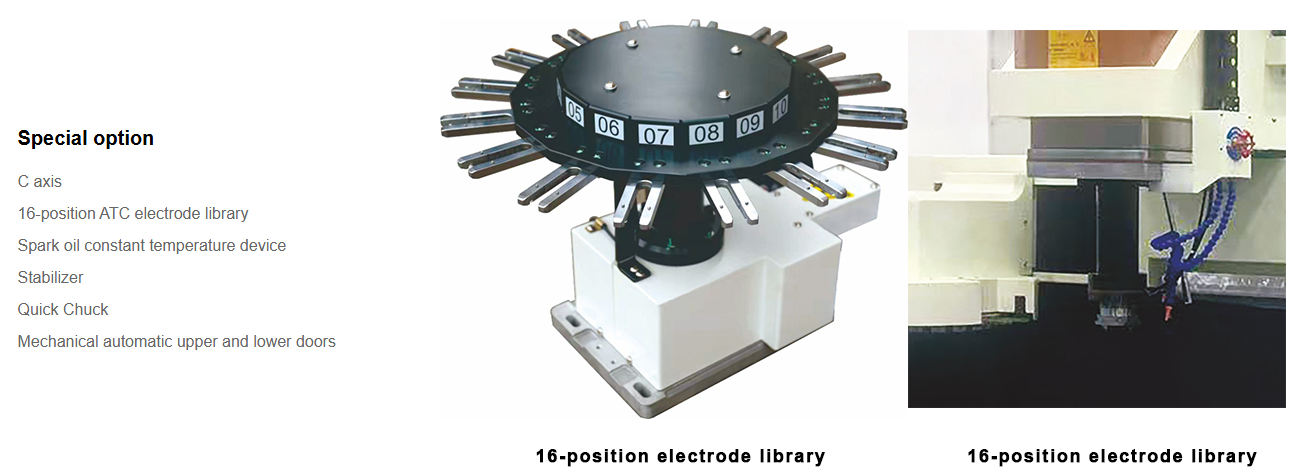

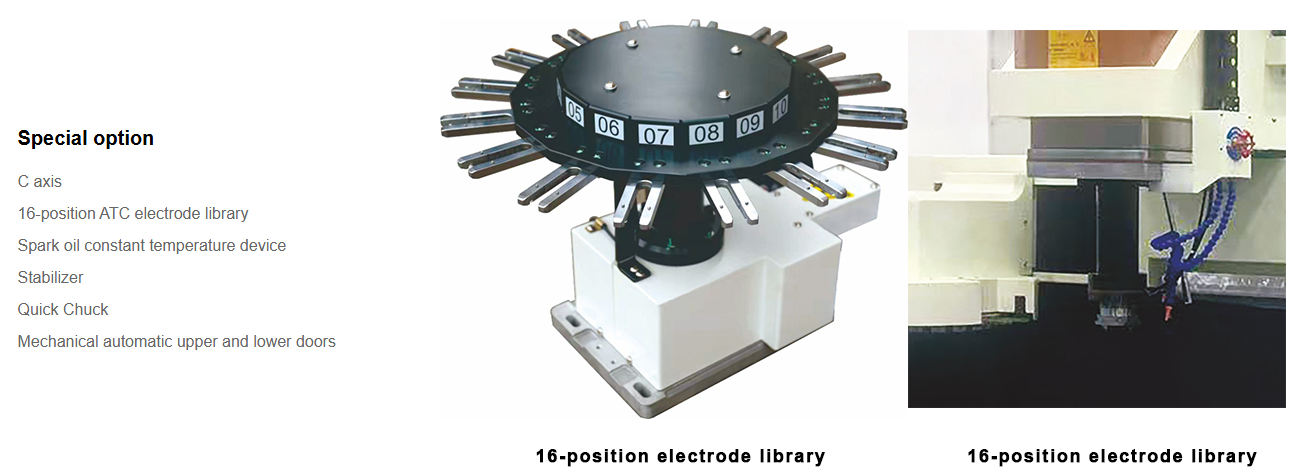

A: With the optional Automatic Tool Changer (ATC) and a well-prepared setup, the AM120 can perform automated, untended machining operations, greatly improving productivity.

Q4: What kind of after-sales support does Mirrordick offer internationally?

A: We provide comprehensive support, including online remote assistance, spare parts supply, and optional on-site installation & training. Our system comes with lifelong free upgrades and unlimited processing support.

Q5: Do you provide custom configurations?

A: Yes. We understand that needs vary. The AM120 can be customized with options like the ATC, 3D probe, and auto-lift oil tank to fit your specific production requirements.

Phone

Phone