Product Introduction

Mirrordick High-Precision Mirror EDM machine AR Series features a high-quality marble mineral casting body, offering exceptional corrosion resistance, vibration damping, and long-term structural stability to ensure machining accuracy and equipment longevity.

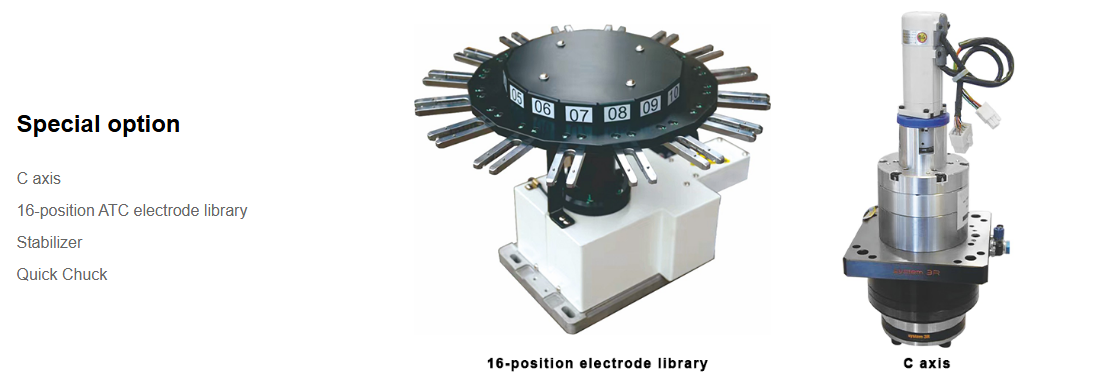

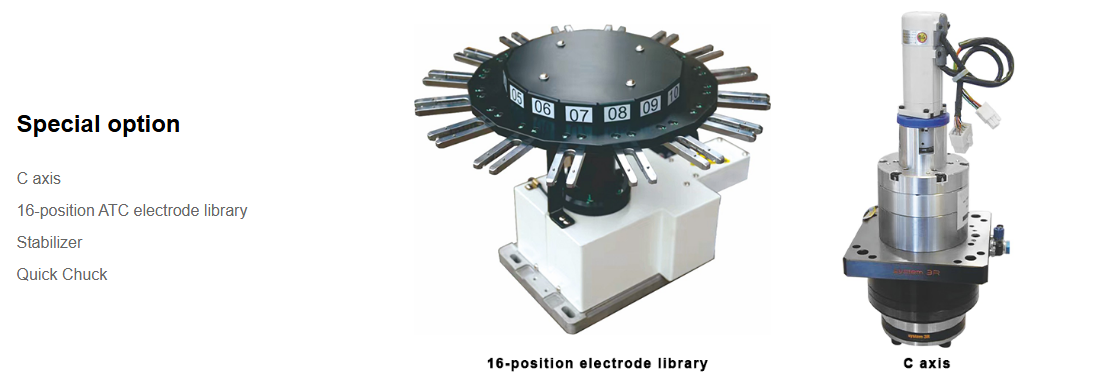

This series features an automatic lift oil tank, a built-in oil reservoir, offering a compact structure that significantly reduces floor space requirements while enhancing the machine's premium, sophisticated appearance. Users may also opt for a 16-station automatic electrode magazine, enabling automated continuous operation during machining. This effectively minimizes manual intervention and reduces labor costs.

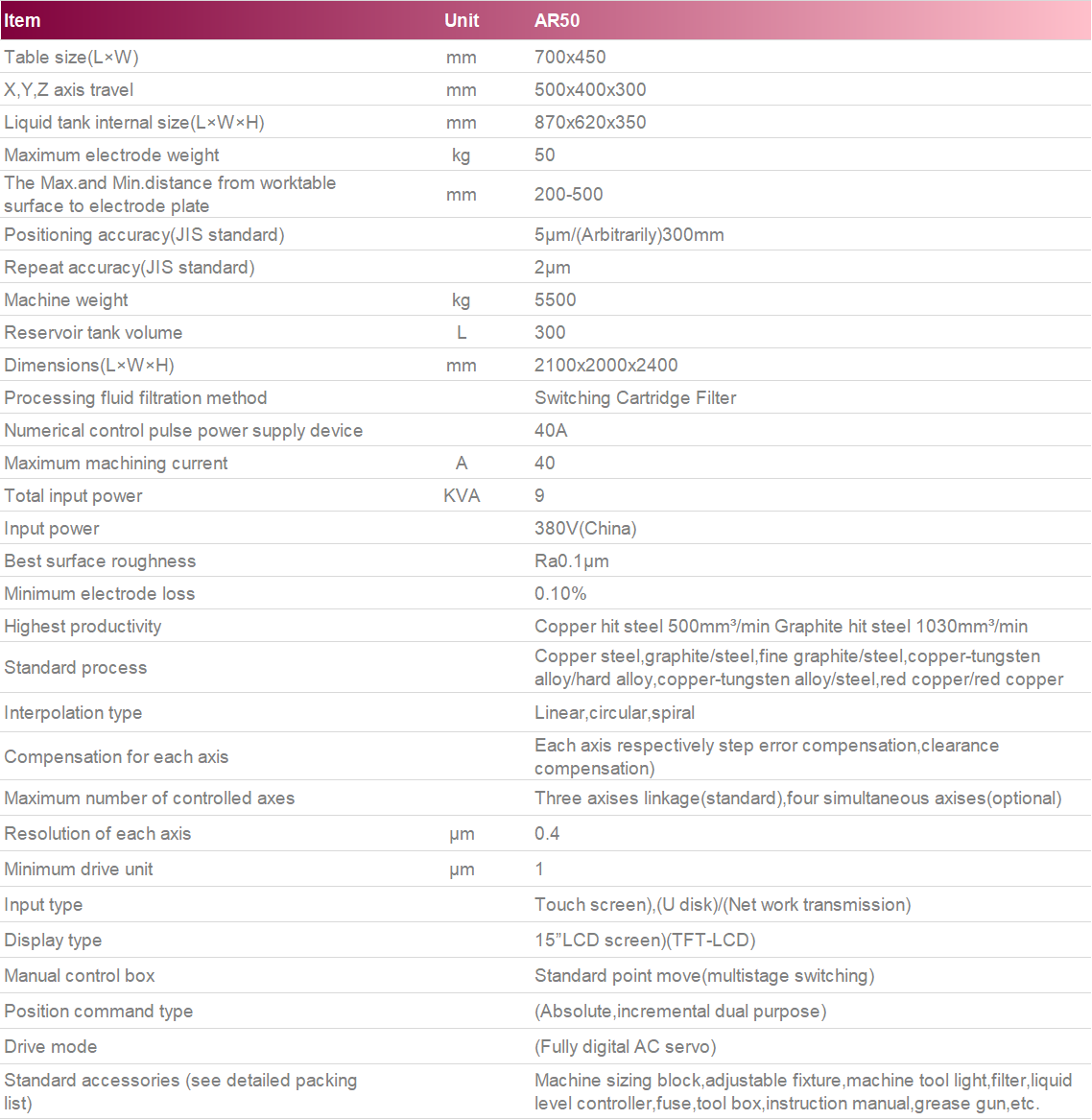

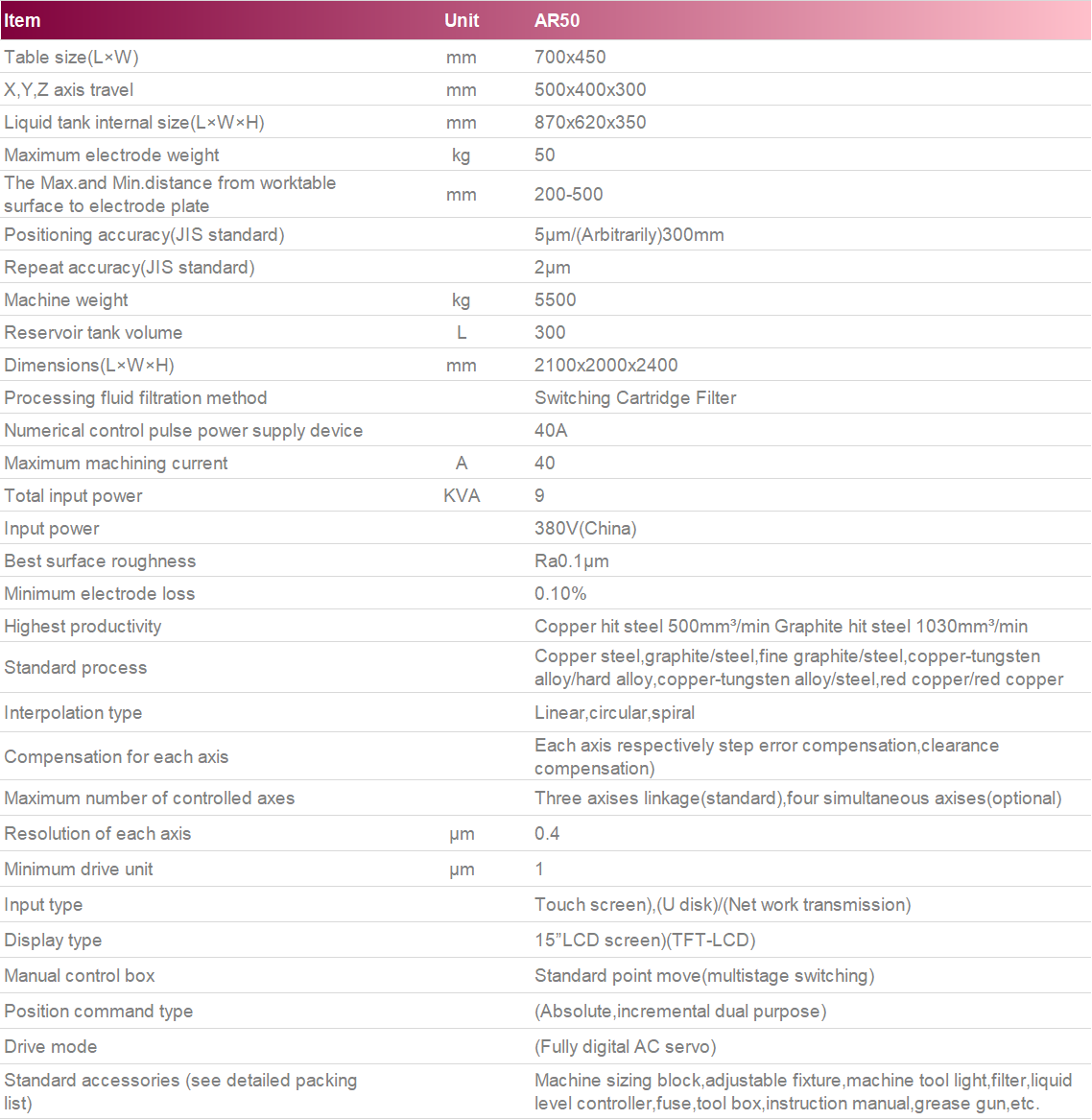

Technique Parameters

Key Features

▶Windows operating system, standard networking function and file transmission,it can be extended to remote wireless operation/dynamic monitoring and to realize internet +automated intelligent production line

▶60 work-pieces coordinate system can be displayed, programming-free,CNC machining programme can be generated automatically according to the interface parameters system

▶The discharge parameters can be modified in real time without suspending during discharge machining

▶According to the processing requirements,the height and interval of the long tool can be set to facilitate slag discharge

▶With a variety of processing functions: 3-axies to multi-axes different trajectory linkage processing, multi-hole automatic shift processing of porous position, transverse processing,45-degree oblique processing, inverted buckle processing, grain surface mirror processing etc., high processing efficiency, small loss of superior processing performance

▶The system is equipped with independent discharge circuits for a variety of material processing: Copper hit steel,graphite hit steel,copper-tungsten hit carbide, copper hit zinc alloy, graphite hit zinc alloy,copper hit copper alloy etc.

▶Made of natural marble, the worktable will move while the head remains stationary during machining

Product Advantages

Superior Surface Quality – The AR50 reduces or eliminates secondary polishing, enhancing product precision and aesthetics.

Higher Production Efficiency – With automation-ready functions, electrode libraries, and intelligent controls, manufacturers can shorten cycle times and boost output.

Seamless Industry 4.0 Integration – Open automated ports allow connectivity with MES and ERP systems for smart factory upgrades.

Stable Long-Hour Operations – Engineered for endurance, ensuring consistency even under heavy-duty continuous machining.

Reduced Operational Costs – Minimizes tool wear, saves on energy, and lowers manpower requirements.

Comprehensive After-Sales Support – Mirrordick provides free lifetime technical support, software upgrades, and process consulting to ensure worry-free operation.

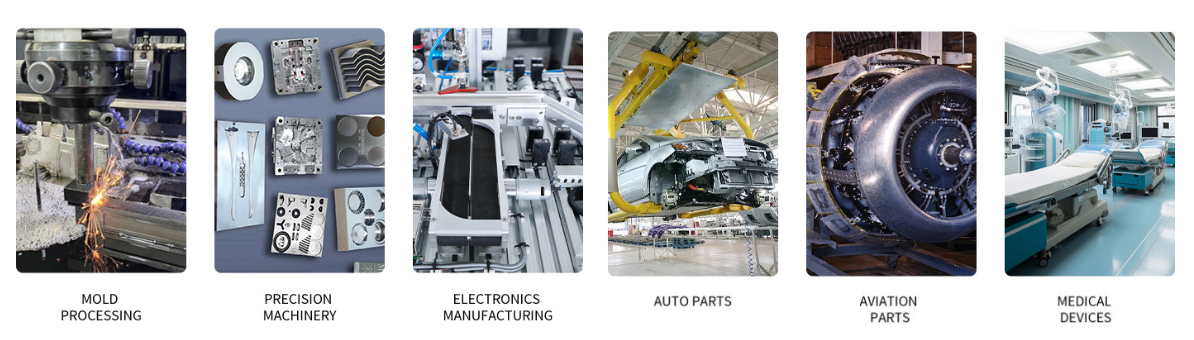

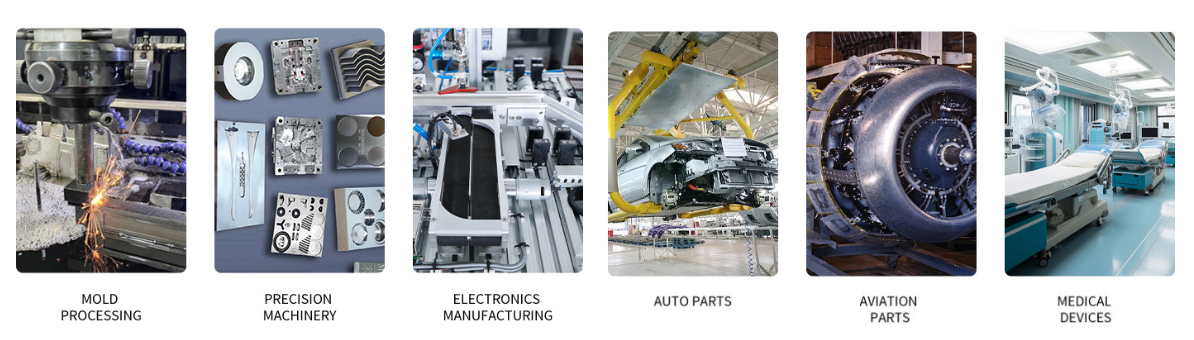

Application Fields

The AR50 High-Precision Mirror EDM machine is ideal for industries where surface quality, tight tolerances, and machining stability are critical:

Mold Manufacturing – Injection molds, die-casting molds, and micro-mold applications.

Automotive Engineering – Precision engine components, electrical connectors, and high-performance parts.

Aerospace Industry – Complex, lightweight components with stringent dimensional accuracy.

Medical Devices – Surgical instruments, implants, and precision healthcare equipment.

Consumer Electronics – Micro-connectors, housings, and semiconductor-related molds.

Industrial Tooling – Dies, punches, and custom tooling requiring superior finishes.

FAQ (Frequently Asked Questions)

Q1: What industries are best suited for the AR50 EDM machine?

A1: The AR50 is designed for aerospace, automotive, medical, electronics, and mold manufacturing, where precision and mirror-quality finishes are essential.

Q2: How does the AR50 differ from traditional EDM machines?

A2: Unlike conventional EDM machines, the AR50 focuses on mirror-surface finishing, higher automation, and smart connectivity, reducing post-processing work and supporting Industry 4.0 integration.

Q3: What materials can be processed on the AR50?

A3: The AR50 is suitable for hardened steels, copper alloys, tungsten carbide, titanium, and other conductive materials commonly used in precision engineering.

Q4: Can the AR50 operate continuously for long hours?

A4: Yes. The rigid machine structure, efficient cooling, and automated oil management system make it highly stable for extended continuous machining.

Q5: What level of technical support does Mirrordick provide?

A5: Mirrordick offers free lifetime technical support, system upgrades, process optimization assistance, and remote troubleshooting, ensuring customers’ long-term satisfaction.

Phone

Phone